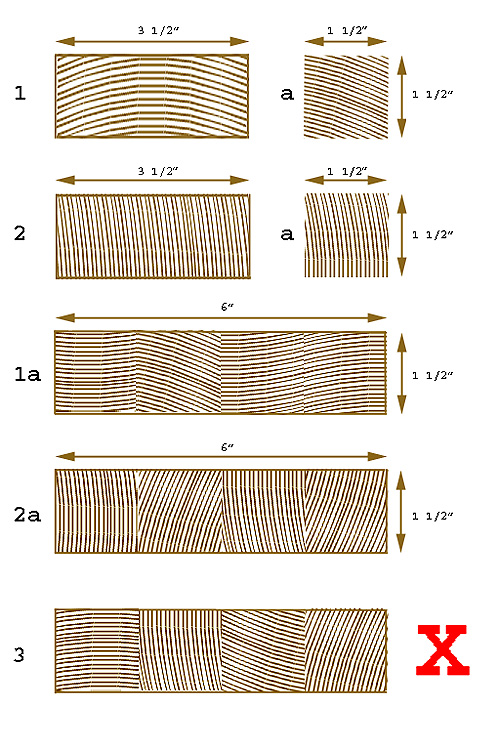

Below is an illustration I made up to try and describe grain orientation and what is considered common practices. The names are also common names although by no means an exaustive list of all the potential names used. The opinions expressed by me are in the context of what I would consider best practices for blade construction using commonly available wood at a moisture content of 12% or less. Other restrictions and conditions may apply.

1 - Horizontal grain/Plain sawn

2 - Vertical grain/Quarter sawn

1a - Prefered layup method for horizontal grain. Alternate curvature but maintain horizontal grain orientation. This layup will be more elastic through its thickness than a vertical grain layup but is more prone to warpage and will experience its greatest deviation through its thickness as the moisture content changes.

2a - Prefered layup method for vertical grain. Alternate curvature but maintain vertical grain orientation. This is commonly considered the most rigid through its thickness and least likely to warp layup. It will on the other hand experience the greatest deviation in its width as the moisture content changes.

3 - Umm, just don't do this. As wood expands and contracts seasonaly the most through the growth rings this yields unpredictable and potentially undesirable results.

Conclusion:

Editors Note:

On request of the author the following was updated

as noted in this comment

Comment

2a - is considered best for blades due to its rigidity and its resistance to warpage.

1a - is next best

3 - is the least desirable

Disclaimer: Wood used to be a living breathing organism before harvest and processing as a result every single piece is as unique and diverse as the human race. It is only possible to try and predict woods behavior based on collective observation, labratory tests and an understanding of woods structure at a cellular level. There will always be exceptions to what is considered "normal" behavior for different species of wood.

Hope this helps a bit. Sorry for the qualifications and disclaimers but....

nuts