2 highschool students from northern ontario Canada,are undertaking a very ambitious project and will be building a Wind Turbine capable of producing over 500 watts in very low winds and peak at over 1000 watts in moderate winds. This wind turbine will be built using as much recycled material as possible and will use wind power which is becoming a very attractive alternative to the rising energy costs of electricity.

-We will be building a 12 volt machine that will be 3 phase.

-We will have 4 coils per phase consisting of 33 turns of #14 magnet wire, with 2 strands of wire in each of the 12 coils.

-The stator will be 16" in diameter and will be 1/2" thick.

-We will be using 32 magnets total(16 per plate), puchased from wondermagnet.com(our hosts here  )the size of the magnets are 2"x1"x1/2".

)the size of the magnets are 2"x1"x1/2".

* I will get into the rest of the parts and the details as we get to that particular stage of the process. I have built 2 machines prior very similar and i have seen over 1000 watts at times and this machine takes care of the electricity requirements at my northern ontario property. I am very happy with the machines output and its overall mechanical stability.

so here goes with some pics and what we are trying to accomplish. The boys are doing all the work, and i am just supervising and it is very enjoyable to pass on what i have learned on this site. Thank you to all who have gotten me to the stage of being able to help others like i have been helped. Your time was and is always appreciated. It is what makes this site a true gem on the worldwide web for sure.

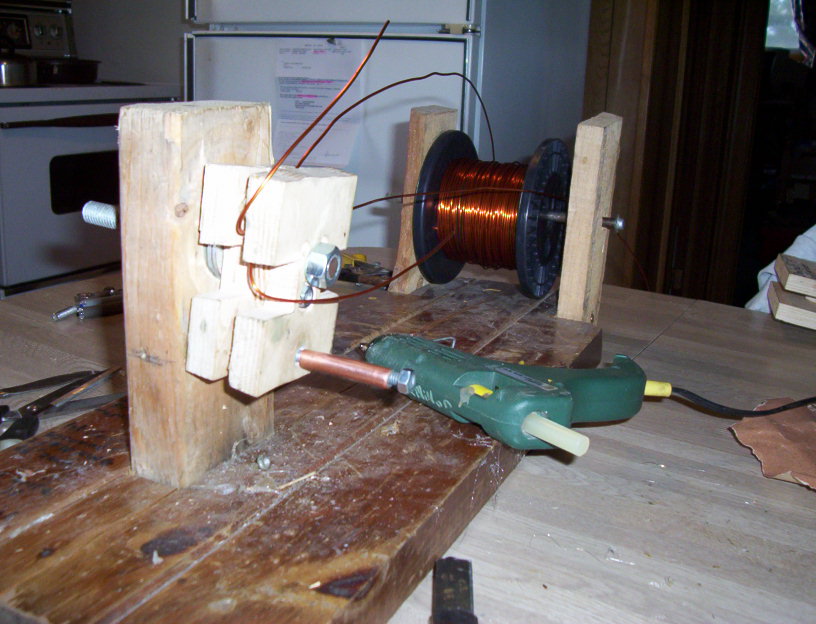

The first thing we did was to make a coil winder. We used the exact model that is in Hugh Piggots book(available here by our hosts). I did change the inside piece a bit and made it go to a point so we could get our coils into our stator size. We lose a bit of power to cancellation, but i have found it works real well anyhow.

I like to use a bit of glue here and there from a hot glue gun. I find it helps to keep the coils together while i try to put some electrical tape on them once they are taken out of the coil winder. I also made a cardboard cutout of the exact size of my stator. I then made cardboard shaped coils and drew in all my lines where the magnets should sit, and the exact position of where the coils will sit. The hole in coil should be the same size of the magnet you are using(or close anyway).

I also use ordinary boat fiberglass(resin), and mix in some baby powder to make the fiberglass resin go farther.. i think i use about 2 contatiners of baby powder for each stator.

the only other thing we did on day one was to cut out 2 pieces of fiberglass to put in the stator mold. One piece to cover the top of the coils and 1 piece to cover the bottom. lots of fun