For those who were interested:

How it works:

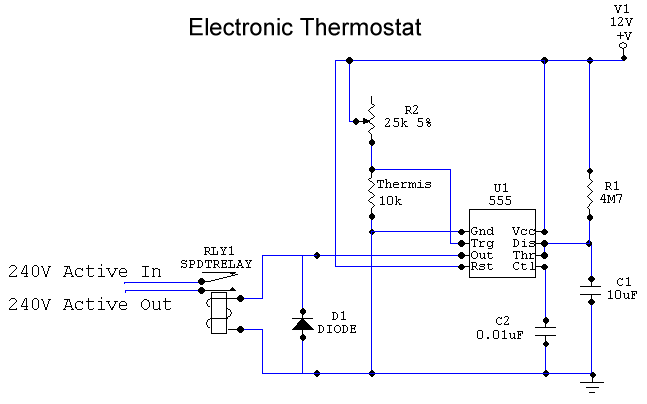

The resistance of the thermistor decreases as it heats up. The variable resistor R2 is set to a value such that when the the temperature rises above your set value, the voltage across the thermistor falls below 1/3 of the supply voltage. This turns on the output of the 555 chip, which switches on the relay. The output will stay on until the temperature drops enough to bring the voltage across the thermistor above 1/3 of the supply voltage, at which point R1 and C1 ensure that it stays on for an extra 50 seconds or so (this is to prevent the compressor being switched on and off too rapidly).

This is how the prototype currently stands. I was intending to use a low-power CMOS version of the 555 chip to extend battery life, but now that I'm planning to add a rechargeable battery (that charges when the freezer motor is running) I'm not sure that the efficiency improvement is worth chasing.

I'm still trying to improve the efficiency of the old freezer, so I visited the scrap metal guys on the weekend and found a nice bit of extruded aluminium channel (about 140mm wide and 600mm long). I'm planning to attach it to the hottest part of the freezer body and have a couple of old PC power supply fans blowing on it. They will be driven via a transistor, which is switched on by the output of the 555 chip (so the fans will be on when the relay is on).

As I said before, it's all good cheap fun. ;-)

BTH