I was able to do a few wind tests today. First My grand daughter and I tested her small science fair dual rotor. This Is the alt with 2 stators. One stator (delta jerry riged) is wound with 200 turns #24 gage and the other stator is wound with 116 turns of #21 gage (star with extra helper turns).

I also tested the 6 pole 3 coil, 3 phase motor conversion test alt.

I used a 2.5 hp tredmill motor with a 24" air mover blade to provide the wind. The tremill motor gets its DC power from a fullwave bridge of 4 25 amp top hat stud type diodes mounted on a heat sink. To smooth the DC a 3,000UF/350 volt electrolytic cap is used.

AC is supplied to this doide package from a 4,000 watt, 120 volt variac. The variac provides 0 to 140 VAC.

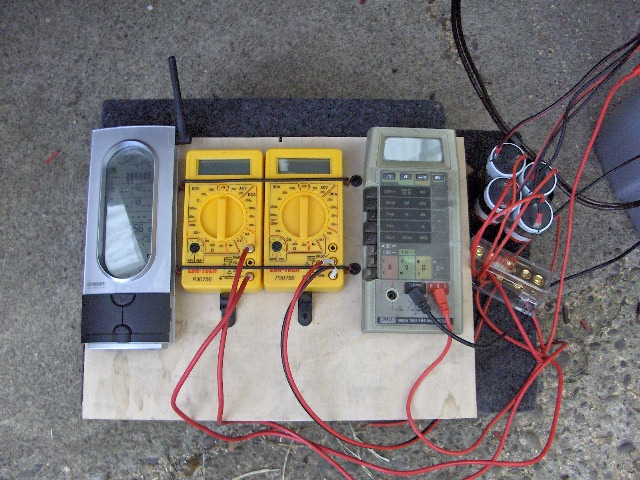

I'm useing an Oregon Scientific amamometer for wind speed measurement. Voltage and amperage are tracked by a Fluke true rms meter plus 2 small HF meters for voltage and amperage readings.

Heres the anamometer.

Here are the meters and the small batteries used for the small dual rotor disc alt.

Here is the variac and an AC clamp on amp meter to track amps going in.

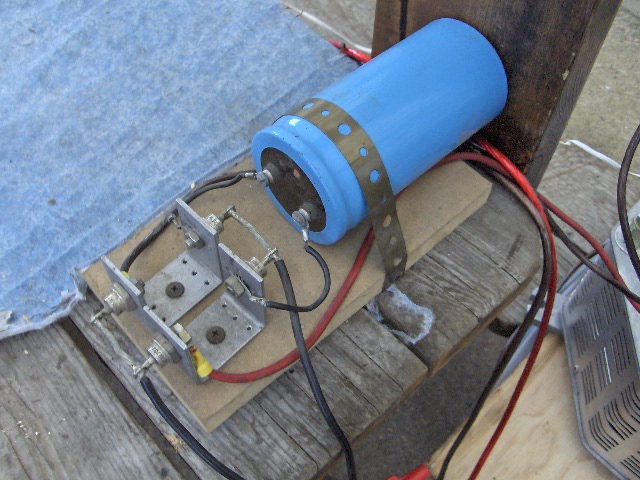

Here is the diode group and cap.

Heres another shot of the variac, meters and the anamometer transmiter.

Heres were all the wind comes from, tredmill motor and blade.

I tried several blades on the small disc alt. This blade from a 20" box fan was the only one fast enough for any measureable output. You also see the amamometers wind cups sensore generater thingy.

This is looking the other direction.

Heres a glimps of the covered area. Its sorta walled in on the sides as well as a roof. Its a fairly closed in area accept for the wind entrance and exit.

Now time to test the 6 pole, 3 coil, 3 phase ac motor conversion. This is the back side. I'm using 49" 3 blade, Jerry blade on this one.

This is from the front side.

Heres the complete setup.

Here are the doide groups for either star or delta/jerry riged conection.

Here is the large 2 volt cell I used on the 6 pole 3 phase alt. It measures 5"X6"X15" and its real heavy. During all the testing this battery went from cold 2.05 volts to 2.15 volts. Its a big load for these small amp readings so it was a vary stable test load.

Test #s on the small disc alt. I could only get a good reading at a littel over 20 mph on this one. Things were starting to shake abit.

Star at 23.3 mph .29 watts. Delta/jerry riged at 23.3 mph .71 watts.

Test #s on the 3 phase, 3 coil, motor conversion.

The anamometer gives an MPH reading every 60 seconds so it was a littel hard to track mph #s so I took a reading over a 3 minute period each.

Star 15-16.8 mph, .4944 watts. Delta/JR 15-15.9 mph, 2.03 watts.

Star 17.9-20.6 mph, 3.1 watts. Delta/JR 17.4-18.3 mph, 3.36 watts.

Star 23.3-24.2 mph, 9.576 watts. Delta/JR 19.7-23.7 mph 10.0405 watts.

It is aperant that stars low wind speed preformance falls behind but catches up in the top end high wind speeds.

However I have not wound the star cheater coil yet. After I do I'd expect 2 phase styles to be real close at very high wind speeds. Its nice however to get better power in more normal or avewrage wind speeds.

It is also aperant that the higher power delta is needing a larger blade at the very high wind speed since it apears to make more power, it naturley would need a larger blade.

It was nice to see how it acts at 15 mph though. I don't think the cheater coils would brought star up to delta/JR at the 15 mph mark. It would have helped a littel but not much.

It will be intresting to build a full size 9 coil, 12 magnet alt and run the same test. I'm now thinking along those lines. That for sure will take some time. Most likley worth looking into though.

Well more tests to be done.

JK TAS Jerry