Story of my 9ft, 4 bladed, dual rotor, 12volt, wind genny for low winds.

Summer winds average 8-12 mph during the day. Winter wind averages 6 mph with occasional gusts to 30. I figure with a 4 bladed prop I can get lower start up and maybe get my cutin around 120-130rpm.

My magnets are wedges 1.57" x .78" x 2" and are only 3/16 thick in a 12-9 configuration. JB welded to the 10" Volvo rotor and a 12" cement cutting blade. I plan no casting on the rotors.

Coils are 100 turns of 18awg mag wire and I am bringing all 6 ends down the tower .

The stator is cast in Bondo fiberglass resin in a fiberglass sandwich.

This shows it only 1/2 full.

7 inch offset for furling and tail mount is 45 degrees over and 20 degrees back.

Tail shaft is steel square tubing 5 ft long with a 5 sq ft aluminum "feather" bolted on.

I hope to set it to start to furl about 20-25 mph.

All bolts are stainless steel on the spindle and I can detect no cogging at all.

At 120 rpm during testing I measured about 13 vdc using Jerry rigged 3 phase wiring open circuit. (3/16 spacing )

I'll have all 6 leads to test with once it's flying so I can determine the best configuration for my conditions.

I got a bunch of 6amp diode bridges cheap so I am leaning toward the Jerry rigged because I will see less current through each bridge. I can parallel up a bunch and keep it in the safe range I hope.

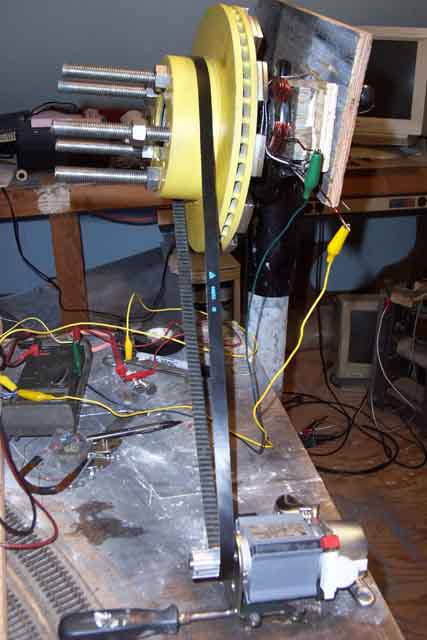

Here is how I drove it at 120 rpm for testing.

This is a previous 4 bladed (3 ft) prop and I plan to copy it for the 9 ft one. This went together easy and was a snap to balance. 9ft one will probably be made of laminated cedar.

It now flies (with a 7 watt stepper generator) where the 9 ft genny will go.

On a 20 ft aluminum antenna mast mounted 16 ft up on my shop.

(Anemometer is a bike computer, works great)

Of course the big one will have guys on it.

I want to thank all the members of this board for the testing and trials they did so I didn't have to do nearly as much. Keep it coming.