It's Been a few weeks since I've had a chance to do any work on the genny. Now that business trips and vacation are over, It's time to get back to work.

I have finally finished work on the rotors. I've shown them in previous posts so I won't show them again until the assembly is ready.

Here's a picture of the Stator that I decided on. It is made out of phenolic and it worked quite well. at 3/16" thick , it appears to be quite strong. I originally was going to drill a 1" hole in the middle of the coils, then decided not to.There was no need, besides it would weaken the plate. The larger holes on the outside of the stator plate are for the standoffs to position the stator between the rotors.The design is for 18 coils spaced evenly on center.

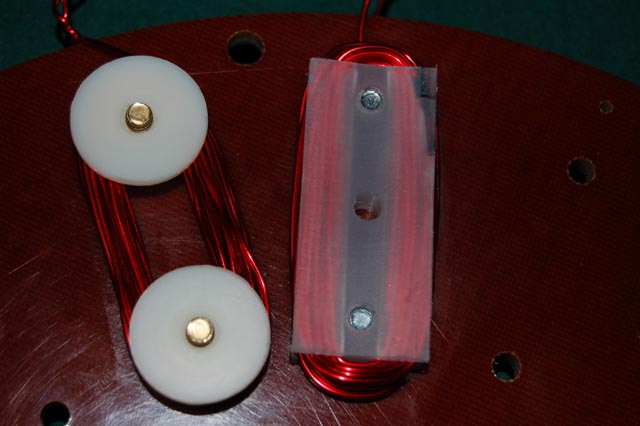

As you can see by the picture below I have two different types of prototype coils.

The original design for the coils called for 2 standoffs screwed directly to the plate as seen in the picture above. Unfortunately, this required the coils to be wrapped while attached to the plate. The result was coils that were loose and wound by hand. I rethought the design of the coils and came up with an idea to solve this problem. I made a different type of retainer for the coils that allowed me to wind the coils in the lathe, keeping proper tension on the wire to produce a tight coil as in the picture below. I plan to make these retainers out of phenolic as well.

I made a fixture that allowed me to wind the coils and then attach them to the stator plate. This allowed for greater flexability while providing me with the ability to remove and replace the coils if needed.

After mounting all coils on both sides, I will connect them in series. This will give me the 18 coils required.

When I finish the parts and assemble the stater I will post again on the results and any problems encountered.