Hi all, I just thought I would just post a quick note on my motor. Things haven't really moved much I have been on holiday and just got back to work on it. Not much done today, just stripped it down and had a nosy around. Here are some pics:

Much bigger bearing housing than last time, the whole thing is massive, it looks to be very well built.

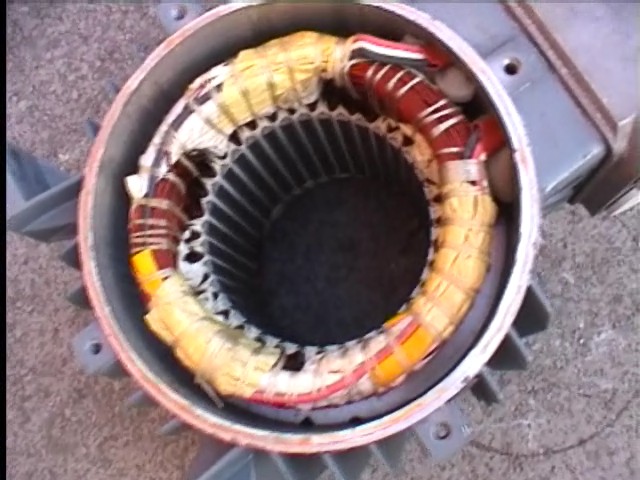

Theres the rotor, very big plenty of room for my mags, not sure what size im going with yet, I was thinking of 1/2inch dia by 1/4 discs. I've still got to work everything out yet.

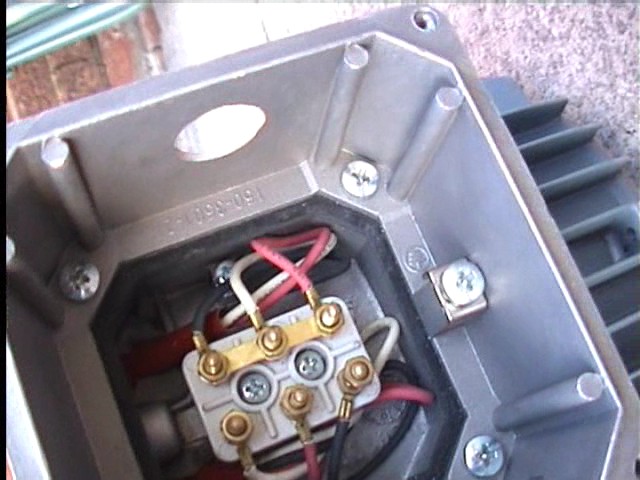

There's the wiring, not sure how to use this yet as my 3 phase knowledge is limited. How would I connect my rectifiers to that??

There's the main motor assembly, very well built. The stator has 36 slots on it.

So far the project looks promissing and should hopefully make a good genny. It bears a very strong resembalance to Zubbly's 'production run' motor, almost all of it seems exactly the same except the voltage/current ratings. His voltage is higher but my current is higher. Like Zubblys it is IP55 rated, so it should be water proof??

Zubbly if you read this could you give me some word on that motor you had, how well did it work out? I couldn't seem to find any follow up of that one.

I dont think this motor has even been used yet, or it has had very little use, everything seems new and clean. I think it was a great ebay bargain at £10.

This time everything is going to be done by the book. Going to use Zubbly's method of creating a cage for the mags. Mag wise I'm not sure how many rows yet but I'm going with multiple disc mags on 10 degree skew, am I correct in saying that one pole should fit inside one coil??. One thing I have noticed is that the shaft is a lot harder to turn than the last motor I had, but I think the bearings were badly worn on the last one.

Any thoughts/comments on how I should proceed would be great.

Thanks Andy