Hi this is a diary of a windturbine I built a couple of years ago. I wanted a source of power to get us through the winter in a mobile home while we waited for mains electricity to be installed.

I had never done anything like this before so my first thought was to use a car alternator. I played with one unsuccessfully for a while before finding the Otherpower website. I was very impressed with the 10' diameter turbines but decided to try to build one similar to one of their earlier attempts.

As funds were limited I decided to try and keep it simple by making it with one rotor and a metal form to attract the magnetism trough the coils. I also made the fatal mistake of not making it furl.

The pictures below show how it went and also show how many mistakes I made along the way!

This is my brake disk all cleaned up and ready for the magnets. I bought 12 2" by 1/2" magnets plus magnet wire from Forcefield

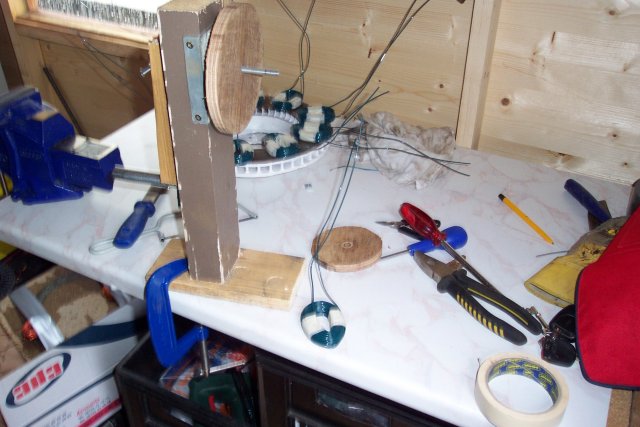

This is my coil winder and one of the coils. I think they were about 65 windings of 14 guage wire (approx 2mm). I also think I made them too thick for a single rotor system.

This is my daughter Rachel standing behind the three phase stator before pouring.

The magnets spaced out on the Volvo brake disk.

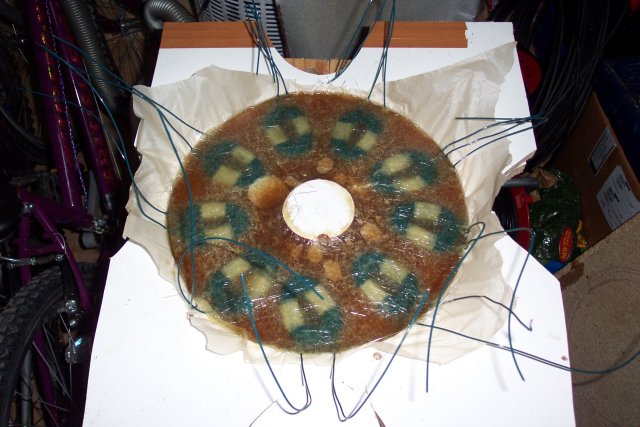

Ready for pouring!

This is the rotor with the resin poured and the metal ring beside it. The ring was made of short bits of metal taken from old transformers and pressed into a chip board form. The theory was that this would help reduce eddy currents.

Dooh!!! I guess something moved when I placed a weight onto the mould.

I tried it anyway but couldn't get much power from this stator. See below for plan B

Because I was using only one rotor I decided to try single phase with 12 coils this time. I linked 2 six's in series and then joined the two circuits in parallel. After a lot of adjustment and replacing the blades this worked very well giving me up to enough power to keep my batteries charged.

This is me fitting the rotor. You can see the metal disk hanging off the back. When this is lifted into place it thumps onto the back of the stator and is hard to get off. I think this was a cause of quite a few of my problems as it probably deformed the stator.

This photo is of the first time I raised it. We had an old telegraph pole outside our mobile and I mounted it on that. I eventually raised it much higher, put larger blades on it and extended the tail.

This worked great for a few months until it blew up in a storm one night. After that I put the original 3 phase stator onto it but never got the same power again.

Giving power to keep us warm on a cold winter evening.

Many thanks to the guys from Otherpower who were so helpful everytime I asked questions. Without your help I could not have done it.