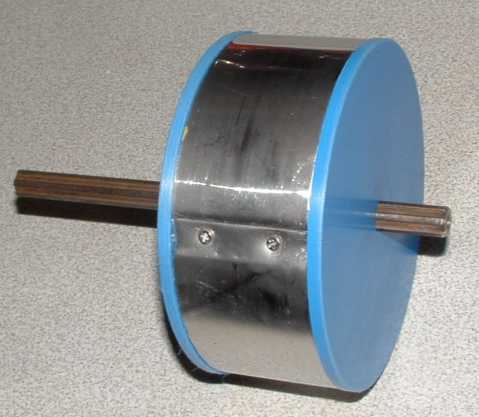

This is the second RACA rotor completed and covered with a 2" non-magnetic .01" stainless steel band. The shaft is recycled from an old deep well pump. It is splined and will be easily coupled to the drive device.

There is only 1.5 cubic inches of N40 magnets in the rotor. The stainless steel screws tighten and hold the 16 magnets in place.

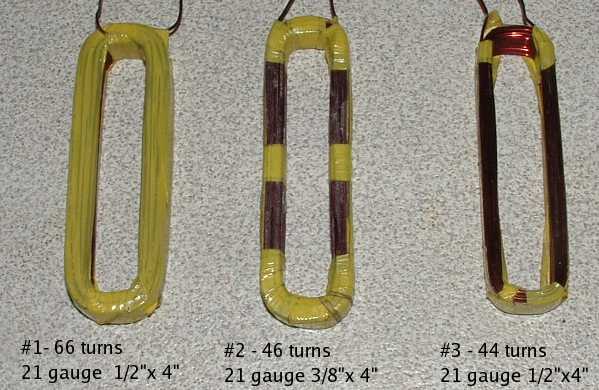

The coils pictured next are several types that were tested and recorded.

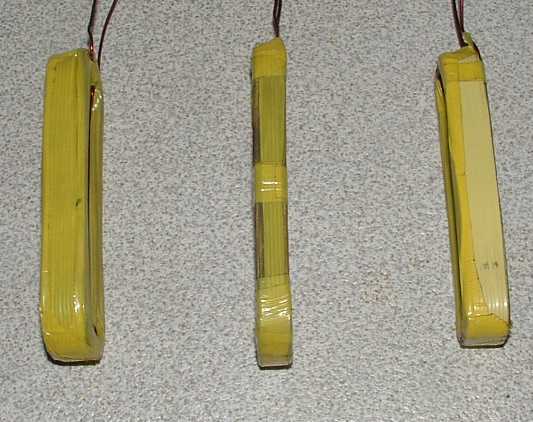

A side view shows the thickness or height of the coil.

Because the rotor spins very true I was able to close the air gap from the rotor to the windings to .025 of an inch. The tests were done on my drill press with a single coil. Readings were AC Volts across a 6 volt automotive bulb and AC Current through the 6 volt bulb.

Coil------RPM------Volts-----Amps

-#1-------600-------3V ac-------1.68A ac

-#1-------990-------4V ac-------2.63A ac

-#2-------600-------1.5V ac-----1.5A ac

-#2-------990-------2.9V ac-----2.15A ac

-#3-------600-------1.44V ac----1.28A ac

-#3-------990-------2.77V ac----1.87A ac

Using coil #1 design my voltage accross 16 coils at 600 rpm will be: 48Volts Ac. 1.68Amps 80 watts ac.

Compared to the air 403 which puts out 81 watts at 600 rpm.

There was very little difference between coil #2 and #3 this was to my surprise . It seems to make little difference when the height was changed. Other than that. my test unit performed as expected. The total cost was $60.00 for magnets and wire and plastic. I expect the unit to be completely assembled before weeks end. I have enjoyed building and posting the results. Please feel free to copy my design and enjoy.

Joseph.