After a lot of tinkering, I have decided to go with a dual rotor setup with some real magnets.

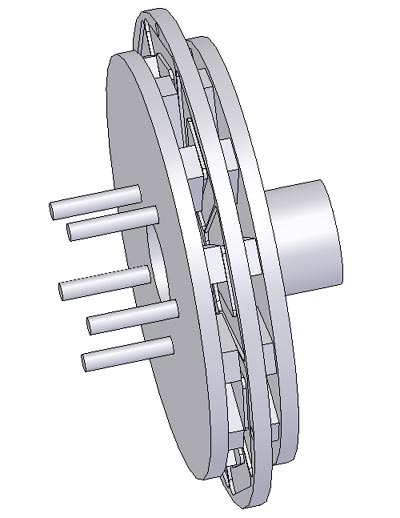

Here's what I have drawn up so far for the design.

Already on hand is the spindle - 2500lb trailer repair spindle, 5 lug hub, bearings.

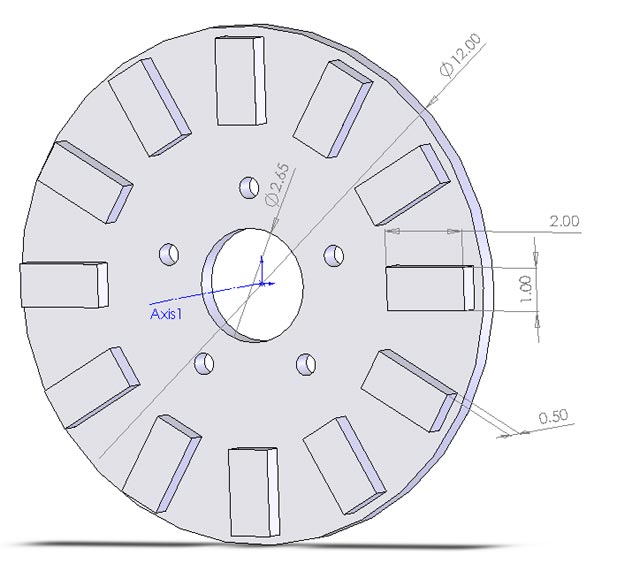

The mag discs will be 11" cnc machined 1/2" thick. 12 mags 2 X 1 X .5

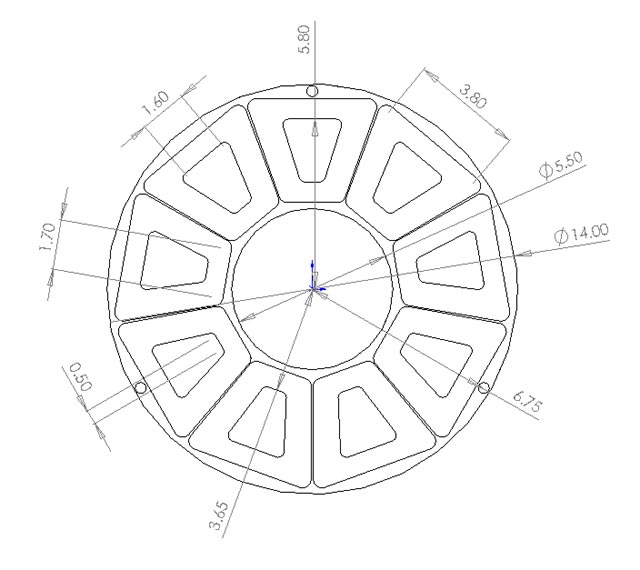

The stator will be .5 thick poured plastic.

Magnet face to magnet face airgap .550 minimum. Once the proper airgap is determined, I will add in an aluminum spacer between the magnet discs, just large enough to clear the studs to help prevent any twisting.

Magnet disc:

Stator (which will be elongated at the mounting bolts to provide more clearance - round was easier to draw)

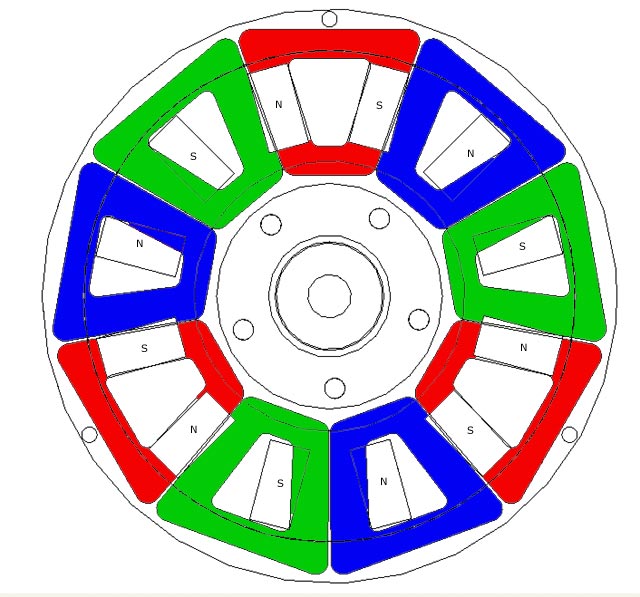

Actual alignment/spacing of the mags/coils as drawn:

As soon as I have the money to buy mags & material, I will be setting up to start cutting. X-mas isn't the best of times to start a project, but here it goes.

This will be driven by a 7 ft 3 blade.

I'd appreciate any comments or suggestions that can be made to try to improve on the design.