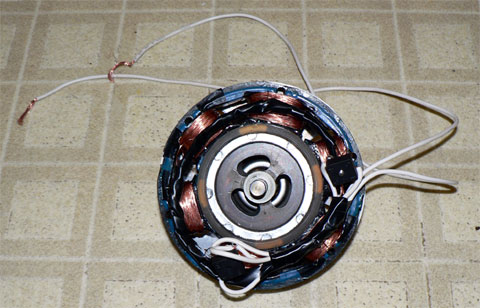

The completed lakewood box fan mini mill. 2.8 amps short circuit. 12v cutin around 500 rpm. Very low budget.

225 turns per tooth 25 awg salvaged wire. 4 neos. Wired 4 lead star. Two rectifiers mounted inside the can, 2 leads coming out. It is definitely not a powerhouse mill, although it is small, lightweight, and can actually generate a couple amps of useable power for very little invested.

It will soon be getting a 3 foot 3 blade rotor bolted onto an aluminum hub. Probably a 1/4 inch headphone jack for slip rings.