This is the beginning of followup on last years debate. It was sugjested that I make an evaluation of these diferant 3 phase wire scheems with a prime driver.

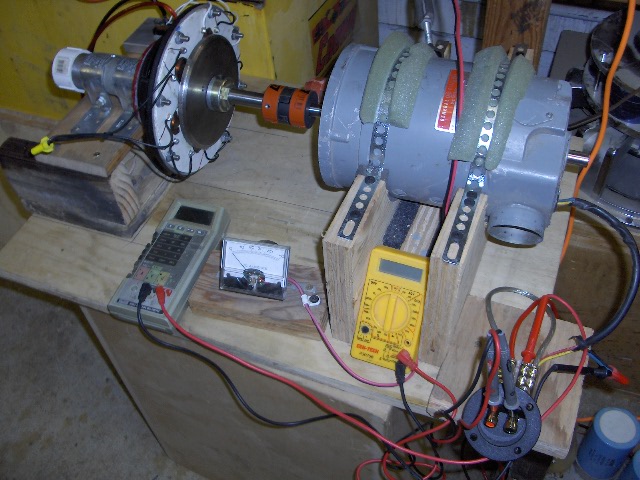

This is a PMA dual rotor alt driven by a motor. The test will determin wich wireing scheem is more eficient.

It is my contention that star is least eficient. I did present some test that indicated this but still the idea was not accepted by most.

The sugjestion was made that I should compair the requiered drive power of both to see witch scheem made the best use of driven power, wire oz. for oz. and magnets.

I've been building several test alts. Last years tests included a car alt, small dual rotor disc alt and 2 types of motor conversions. They all had very simular results as I've found in todays test.

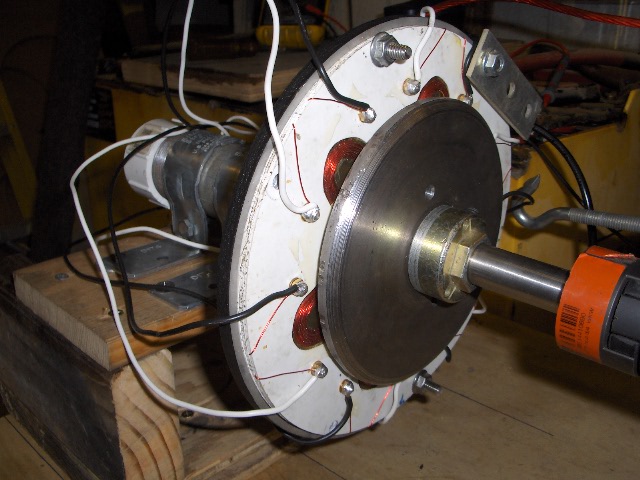

Todays test alt is a 5.125" dual rotor disc alt. each disc has 8 each 1"X1/2"X.25" Neos.

The gap between magnets is about 3/8". The stator thickness is about .25".

2 indentical stators were cut from 1/16" thick fiberglass shower stall material.

All wafers for the 2 stators were cut at once this included the holes for coil placement. The atempt here was to make these 2 stators as identical as posable.

This icluded coil size, shape and posistion.

The star stator has 6 coils wound with 40 turns of # 18 gage wire.

The "Jerry Rigged" stator was wound with 150 turns of 24 gage wire. This stator was actully wound first. I found that 150 turns of 24 gage fit the aloted coil space very tightly. Thats what I wanted a snug fit so the coils were held in proper alignment.

Next I wound the star coils with 18 gage. The therory was to wind the star coils with 1/4th the turn count as "Jerry Rigged". As it turned out there was enough room for 40 turns allthough 37.5 turns would have been 1/4th of the "Jerry Rigged" 150 turns. Last year it was sugested that star needed a few extra turns to make up for its out of phase voltage loss. So I was happy to get star the 10 extra turns.

In star there are at any given instant 4 coils connected in sires. I wanted each "Jerry Rigged" coil to equal the entier turn count of the 4 star siresed coils.

This ment that the "Jerry Rigged" wire would have to be 1/4th the circular mills.

18 gage and 24 gage was a good match for this project.

The star stator is wired in the accepted scheem. "Jerry Rigged" is wired with 6 fullwave bridge rectifiers, 1 bridges per coil and all there dc outputs are perelelled.

I used a GE dc compound wound motor as the prime driver. A 100 volt dc power supply was connect to this motor. The power supply was connected to a 5KW Variac.

This alowed a voltage of 0 to 100 volts dc for the prime driver motor. The driver motor was coupled to the small dual rotor disc alt via Love Joy coupler. A direct conection.

Voltage and amperage were monitored going into the prime driver motor and voltage and amperage were monitored comming out of the dual rotor disc alt. 4 meters at once.

Open volts, loads volt, load amps were recorded for both stators and drive motor during test.

I hope to expand further testing soon to include rpms at diferant loads, temperatures after a set time and stress load to compair the 2 scheems. It is my belife star will run conciderably hotter the "Jerry Rigged". I also belive this acounts for so many burnt stators and coils.

Here are todays test #s.

The load is a 2850 LB lift truck battery configured for 12 volts. Beging test with battery at 12.62 volts at rest.

I ran the Variac up to 100 volts, at this drive motor voltage star produced 14.4 volts open no load.

Same test for "Jerry Rigged" , drive motor at 100 volts "Jerry Rigged" open no load volts 17 vdc.

Next I connected star to the big battery load. Again in star with the driver motor at 100.31 volts and 6.4 amps star was produceing 1.7 amps at 12.72 volts.

For star the means it was requiering (100.31 v X 6.4 amps) 641.98 watts of driveing power while produceing (1.7 amps X 12.72 volts) 21.624 watts.

I remove the star stator and replaced it with the "Jerry rigged stator. Gap was maintained and stator posistioning was exactly the same. The speaker basket stator support mandated this.

Same test. I drove the "Jerry Rigged" Stator up to the exact same 1.7 amps that star was producing and the same 12.72 battery volts. The diferance was at this point the prime driver motor was operating at 5.2 amps at 90.5 amps for 470.6 watts of drive power requiered.

So to produce 21.624 watts output star requiered 641.98 watts while "Jerry Rigged" requiered 470.60 watts to produce the same power. Thats a diferance of 171.35 more drive watts requiered by star.

Next I drove the prime drive motor up to 100.39 volts at 6.4 amps or 642.496 drive watts. At this drive power star was produceing 21.624 watts.

"Jerry Rigged at this prime driver motor power "Jerry Rigged" was produceing 12.74 volts at 2.8 amps for 35.56 watts.

This littel alt is very tiny. I'm going to load it down heavyer at 6 volt and maybe even 2 volt battery to thest the thermal condition.

However I belive these results are scaleable and I intend to dso just that.

I'm working on (as time permits) a 4 ft Hugh Piggot alt with the same tests. Also a 12/9 wedge alt and a 1.5" disc magnet test alt.

I'm convinced the results will be the same. I'll be testing rectangular, round and wedge magnets as well same shapes for coils.

Heres a few pictures of the test set up.

JK TAS Jerry