I wanted to make a small wind genny to go in my garden. It won't have to big enough or high enough to frighten the neighbours into asking about planning permission, so 4ft diameter is what I was aiming for intially.

I don't have any access to welding kit, so I made a stub axle which I propose mounting on some sort of bulkhead.

The shaft was turned down to 16mm od, and the thread is M16, the bearings are twin race 5202 series.

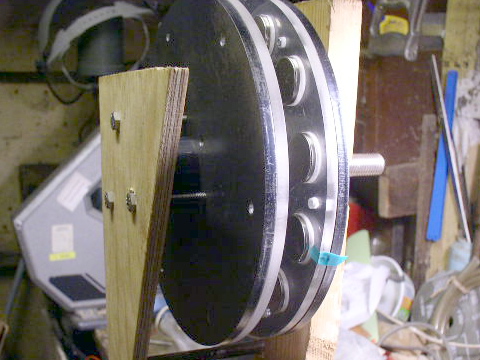

This is a piece of steel tube that the breaings/shaft go into. The Aluminium block is the separator that holds the discs apart, I had to cut it with a hand hacksaw from the barstock. At around 3" diameter this took some time! Then it was bored out on a small lathe. It's retained on the steel tube by grub screws and a sort of circlip that you can't see in the photo.

This is the sleeve on the shaft.

I had two steel discs cut at a local firm by laser. They cost me £10 each. Each disc is 210mm diameter, with a 44.5mm cetral hole to fit on the hud assembly. The perspex disc you can see will be fixed to the steel and will hold the magnets. (12 of 1" by 3/8" N42). Three of the six holes in this one disc are tapped to M6, this is for the jacking arrangement.

Here are the discs on the hub, no magnets yet, just to show how it goes together.

Here I've put all the magnets into their holes and and the rear disc is mounted on the hub. The scruffy piece of wood is my jacking plate, it's resting on the protuding front of the hub, and the front disc is fastened to it by 3 M6 screws which are in the tapped holes in the disc.

Here the front disc is in position and the wooden plate is about to be removed.

I'm at the testing a coil stage now, more to follow.

Thankyou to all who helped me get this far.