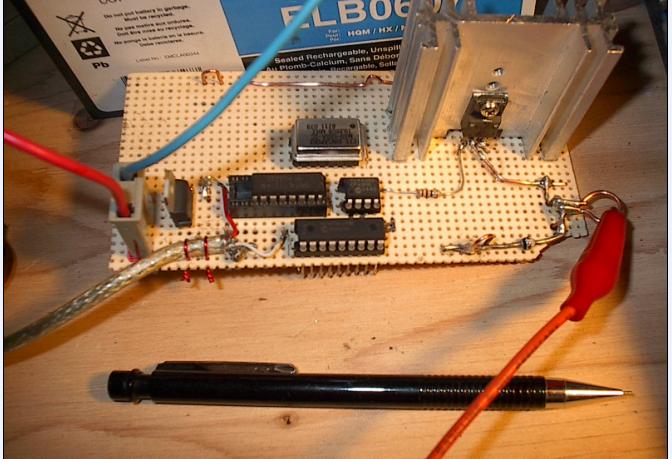

I moved my boost circuit off the breadboard and made it portable

It runs on 6V or 12V

the battery powers a 7805 for the PIC16F88 The clock and a 74LS161

the FET driver is powered directly by the battery , and feeds the FET with the PWM from the PIC.

not shown are the 2 one farad caps in parallel that i use between the alt and the converter also not shown is the pot on the other end of that recycled USB cable , that i use to vary the pwm

the caps serve to sort of buffer the alt from the pwm , and this way the alt can get ahead of the pwm if the wind allows it to

during testing the boost doesnt mind at all if the alt and cap voltage is greater than the load battery voltage

The boost converter can still double as a step down dc to dc converter or a hot wire foam cutter, just by bypassing the diode and the inductor

i used wire wrap sockets , but ended up soldering them anyway

i also put a 10 Ohm resistor between the fet driver and the gate because i thought it may protect the gate a little better than without it

as you can see i now have some more room on the breadboard

the goal of all this is to get some more power from the minigen II during low wind days , the other day when i took it out for a spin , it never stopped turning ,but it would only charge a 12V battery at or over 220 RPM