Now that I've had the 3 foot $40 windmill sitting out back (to test things out & introduce the neighbors to my obsession) I decided it's time to go up to something with some actual output.

The 3 footer has peaked around 2.5 amps charging. Pipe fittings, saw blades, 1/2 X 1/4 inch neos, and I couldn't be happier with it.

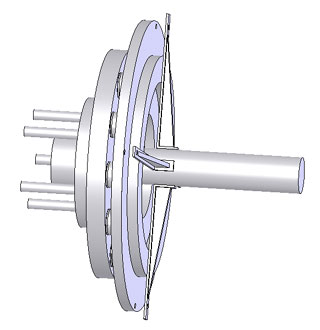

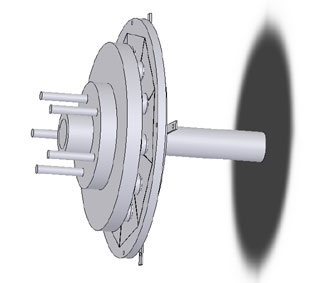

Now comes the real mill. The design is an 11 inch Honda brake rotor on a cut down 3500 lb trailer spindle. It should be bulletproof.

It is all modeled & ready to rip. Just machined the rotor tonight & I'm hyped to get it together.

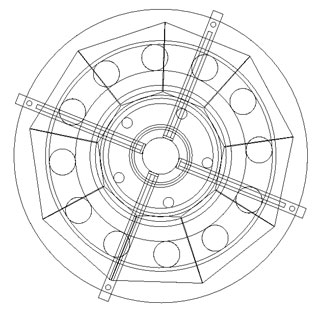

It will be a three phase, 1.25 inch by .5 inch neos (get ready for the order - it's coming soon) and my first attempt at a stator will be with 16 gauge high temp wire. I have been looking into having a laminate custom made, and things are looking good. I think the single disc laminate design with the hub machined to fit into the disc as I have done should completely eliminate any stator rub failure possibility.

Now that the disc is machined (.03 inch deep pockets to locate the mags) I only need to order the mags, get the laminate made, wind coils, & knock out some (ugly as I usually get it) welding.

I'll continue on as soon as funding allows.