In our case where we are now and where we want to get to seem to be the two known coordinates. It is the transitional nodes along the way that are tricky. We started basically with the following system:

Sencenbaugh 14-1000 (12VDC, 1,000 watt) wind generator (circa 1981)

6- 50 watt solar panels also wired for 12VDC

8- L16HC 6V Trojans batteries wired for 1,600 AH @12VDC

A Trace 2512, (circa 1987) modified sine-wave inverter

We also added a small Rutland 903 a couple years ago to the cupola on the garage/shop as our "functional weathervane". The Rutland provides power for the door operators, and a handful of lights, inside and out - an occupancy sensor energizes the inverter when the car arrives.

There's little doubt that we would do things differently starting from scratch now, but most of the equipment, particularly end-use equipment, has significantly improved since we started out. That being said, it has also been a pretty reliable system.

We set out this year to transition the system over to 48VDC in anticipation of the new axial-flux (details previously posted in my diary), but we have numerous low voltage circuits and devices, including lights, water pumps, refrigeration, etc. Here's the progress thus far:

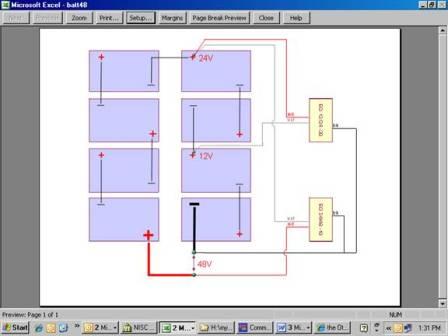

We installed a 48V Outback inverter this summer, and rewired the battery bank for 48V, currently with both 12 & 24V taps. The batteries are balanced using two, Solar Converter's "autotransformers" (equalizers) wired like this:

The Sencenbaugh, and presently the PV's, charge into the bank at the 12V tap. This is also where most of our lighting, the refrigerator and a number of existing small loads are tied. It's less than ideal for charging - we're only utilizing a portion of the available battery capacity directly - but although the equalizers are small (the 12V is current limited to 20A; the 24V is limited at 10A) on average they seem to work well within some reasonable restraints and load management. As designed they allow one to consume, or produce, at considerably higher rates for short durations, and still balance out over time.

We intend to continue to migrate loads over to the higher voltage(s) where appropriate, but were trying to avoid changing every light bulb at the same time we're revamping the heart (batteries and inverter) of the system. We're also hesitant to rely exclusively on the inverter despite the advancements now-a-days in technology and reliability. The water pump was refitted with a 48V motor, and the panel array, if you can call it such, will be expanded and reconfigured next summer.

We're still muddling through many of the details on the wind generator - and learning vicariously through the experiences of folks here - but we wanted to get some lumber drying for the blades. After a bit of research we selected Balsam Fir as one of the better locally available species. It wasn't immediately intuitive that this would be our choice - I generally think of it as being pretty soft, and compression strength perpendicular to the grain is low (which concerns me a bit) - but it has good a properties in bending and particularly horizontal shear relative to it's weight. And, it fulfills a lot of our parameters- locally available, light, easy to work, moderately strong. White cedar was a possible candidate too, being lighter, but is a fair amount weaker. The properties for the Douglas Fir might would appear to bring the strength to weight ratio up to that of Sitka, but I don't think we need the extra strength and the extra weight will be a penalty. So this spring I cut a few logs and my friend Mark did a nice job sawing them out.

Some are solid blocks, presumably for the early run, the final set(s) will be laminated.

My wife and I also managed to fit in a new arrival this fall. A son; "Adler", 09/14/07.

As always, we welcome comments. Regards, -kitestrings