I wanted to replace the 4 foot single rotor we had at our cottage at the lake. It put out 10 - 15 amps and we needed a bit more power. The second reason for changing it was, the 4 foot was having a hard time braking with the 10 - 15 mph winds we encounter. The 6 foot with dual rotors would be a better choice. I searched the board and used 55 turns of 2 in hand #15 wire. The rotors were 10 in with 8 mags 2 x 1 x 1/2 on each rotor. I used 3 foot blades to make a 6 foot diameter.

I had 2 visitors one day and when they saw the performance of my machine, they decided to remove thier Air X machines from thier cottage if I would build them each one. Well they told another friend and I was busy this winter.

This is my build.

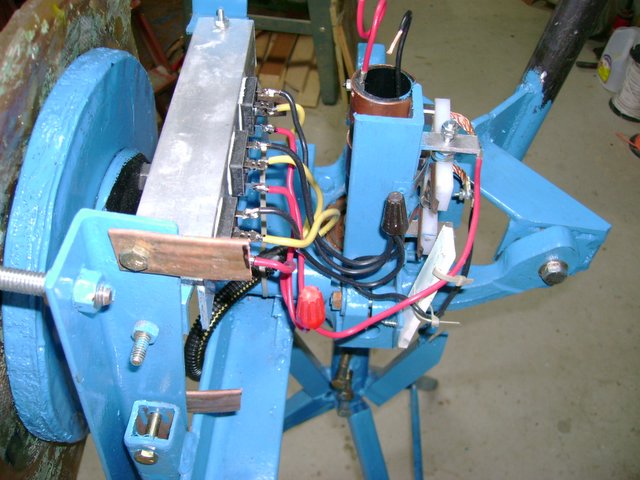

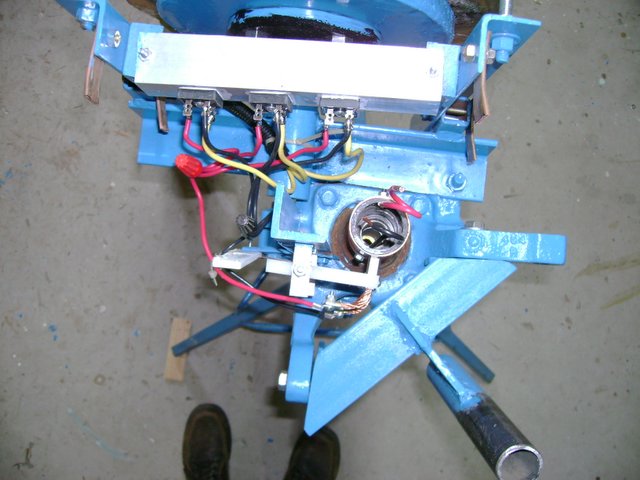

My yaw bearing is a front wheel assembly off any front wheel drive car. You need this as it has a hole in the center of the bearing to run your wires through. It also allows me to use my sliprings and brush towers.

Home made sliprings and brushes

I ended up building 4 more 6 foot gens.

Note on the top right of the picture, you will see a 4 foot single rotor. It,s hanging by a horseshoe,on the end of the rope.

In northern maine and New Brunswick we must have a weatherproof covering because of snow and freezing rain. I use the 5 gallon sized pails that my magnet wire comes in to enclose the generator. Its not that pretty, but it works and they last for a long time.

Here is a 8 foot Dual Rotor with its canopy installed and the heatsink looking out.

Thanks to all you guys that give me advise over the last few years, Harrie, Dave, Hugh, and Flux. I,m retired,what else would I do. Mitcamp