Hi,

I want to share on the forum the success I've had with my PICLOG. Here are the plans for the device:

Click on the thumbnail to see the whole schematic (104kB, 1000 pixels wide)

The plans are found HERE.

Here's another Diary about using the PICAxe to collect data, from Jimovonz (he designed something similar himself): http://www.fieldlines.com/story/2007/5/22/23153/8722

The PICLOG uses a "micro-controller" chip to receive and transmit data about the windmill. The data is transmitted to a computer through its serial port. I think I'll leave the details of how it works to the author; Glenn explains it very well.

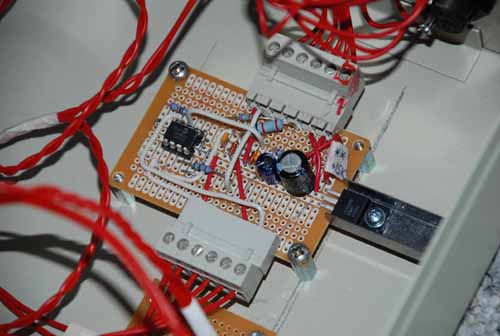

Here is what my version looks like:

Yeah, there's lots of extra space in the box, but I didn't want it crammed, and who knows? Maybe there's bigger and better in the future?

Here are pictures of the testing and calibration:

The anemometer is a story in itself! This is the third iteration, the first two being too small to over come the stepper's "steps". The stepper motor comes from a printer, and the blades are cut out of PVC pipe according to the Zubb-Woofer plan. The anemometer was mounted on a pole for this truck-test (kinda hokey with bungee cords) and I stacked my multimeter and a GPS for correct speed on the dashboard.

The stepper motor wires are connected to a telephone extension cable, the jack for which can be recognized on the face of the PICLOG box below.

Here it is with a bunch of resistors acting as a load to calibrate it. The resistors mounted as a pair are actually the Shunt, where the current is measured.

I did other calibration runs to have some reality checks on the RPM. That's one thing that will take some work - not the fault of PICLOG, it's the low frequency of the alternator.

My early runs collecting data left me looking at a lot of scatter. The obvious culprit was the RPM measurement (the bane of the motorconversions). The frequency output is so low, that in one second the PICLOG can get 3 pulses, and in the next only 2, thus causing a 50% error. To fix this, I increased the period over which the PICLOG counts the pulses to two seconds. This may be enough, but while hand-turning the windmill the output still jumped around, so I may increase the period to 3 seconds.

What this does to the rest of the data is that the current measurement gets more weakly associated with the "instantaneous" RPM value. That means for the same measured RPM, a different current will be read off, if the windmill is speeding up or slowing down in the preceding 2 seconds.

Well, close counts in horseshoes and windmill logs, so I'm still thrilled to see some reasonable data. Here's a sample:

This is miles ahead of where I was last month, and I have Glenn to thank. I also have Lforbes to thank for finding this for me.

Of most immediate importance: it's obvious now that the cut-in is pretty low, but the furling speed is rather high. If the RPM measurements are to be trusted, I think the range of speeds the windmill experiences goes too far on both ends. Re-wiring for parallel-star will probably improve performance over series-delta. Maybe even parallel-delta will be worthwhile (HaHa I only made that remark to make Flux blink! He's warned me about doing that already :-)

Bye for now

Steven