I realised that I might not able to get enough power from the infrequent wind here and just the one PV panel. I plan to use an inverter that will be 'always on' to power some house lights, and this will use it's share of power to run. So I went and bought another 80w. This arrived within a few days and I excited unwrapped and tested it.

I'm afraid it was a bit of a disappointment. It was slightly bigger thanthe previous panel and there were 40 cells on arranged 10 x 4 rather than the 9 x 4 that i had already. That wasn't the trouble though. The problem was that it didn't give anything like the same output for the same light conditions; where the old panel was kicking out 17volts, this new one wasn't managing 12 ! Not good at all. I also noticed that the two 'sides' of the panel were not matched.

I phoned the shop and they agreed after a bit of haggling to have it back. rather than beingsent a duffone again, I decided to go to the place personally and took a meter with me. I had several panels out in the sunshine and in the shade and took home the one that I liked the best along with £10 for my petrol.

The panel is now mounted on the foof and kicking out lots of charge.

Next, I decided to do something with my blades on the wind turbine. If you're already bored with reading this saga, go no further, otherwise....

A few months ago I made some wooden blades instead of the PVC pipe things I had been using. I put them on but was never completely happy, they just didn't seem to spin like I thought they would. One day while i was watching and testing the output I noticed that they weren't doing the job. I confirmed this by quickly swapping back to the plastic set and watched the power DOUBLE; definitely not right.

The wooden set languishedin the shed untill this month when I took them out and had a really good look at them. What i noticed was that the front (wind) side of the blade wasn't as flat as it should have been, it was actually convexed. So I set about cutting more wood off all three blades, eventually getting to a profile that was very slightly concave on this front edge. In taking the wood off, I also sharpen the trailing edge, by the time I'd finished it would take a kangeroo's head off if it was a boomerang.

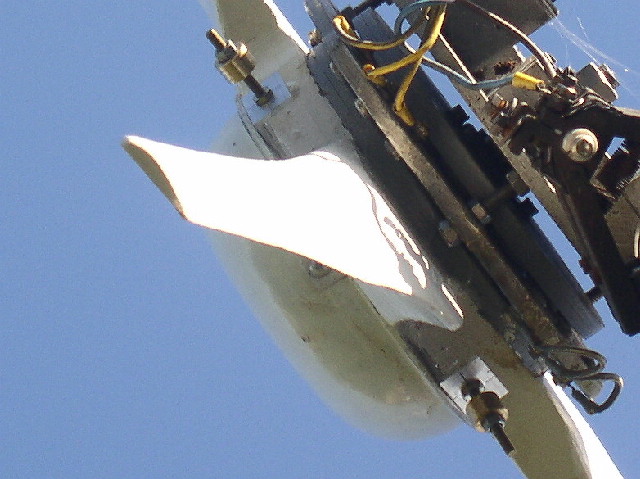

I then made some balancers, I've noticed in the past how much power is mopped uip by even a slight wobble. I'd just made them when I saw a post that refered to them as Jubbly's, perhaps I'd seen them a long while before and they stuck in my mind. Anyway, I made three, and mounted them opposite each blade behind the front plate in the recess between the blade roots...

They are made from 1" brass bar tapped with 2BA thread so that they can be adjusted on the 2BA bolts, and locked with nuts. The bolts go through bits of aluminium angle and I was able to achieve very fine balance once I'd mounted the blades on the turbine.

I finished off by making a nice front boss to cover all the screws and keep the water out, this was all sealed with silicone as were any wood to metal gaps.

The new blades seem to perform much better, certainly adequate for the moment. The main problem will always be the turbulent winds I have here.