Hi

With winter preparations occupying me time for the past couple of months, I haven't been posting much info about my windmill on the forum. Meanwhile, however, I have been testing and collecting interesting info that I've been meaning to share when I had the time to do so.

I assembled a large Toshiba 3-phase 7.5hp motor conversion and I've conducted several tests on it. I've measured open-circuit voltage and the drag the magnets cause as they turn through the stator iron. After crunching numbers on it, I concluded that it would make an excellent 48V generator when fitted with a 12-foot (approx) prop. I cannot put it in service, however, because my workhorse GE is more suited for my 24V electrical system.

Last month, I took that GE down for maintenance. Nothing was particularly wrong, but it seemed like a good idea to take it all apart and check it over. Moreover, I had some improvements in mind, and it was time to get them done.

With the whole tower down, I took the blades off, the tail off, the generator off, and I even did a bit of unwinding of the power wires. A few turns were necessary. With the tail removed, I regreased the whole hinge assembly and checked the bumper. The important change to the tail was its weight. I've always watched the furling of the tail, by eye and in the datalogger data. I have always considered it to be too early. Both the motor and the blades can handle a lot more speed than I have ever been able to measure. With more speed comes more power to be captured.

The tail vane is a simple plywood board. To add weight, I epoxied a sheet of steel to it and placed a copy of the board on top. Same shape, twice as thick, 3 pounds heavier.

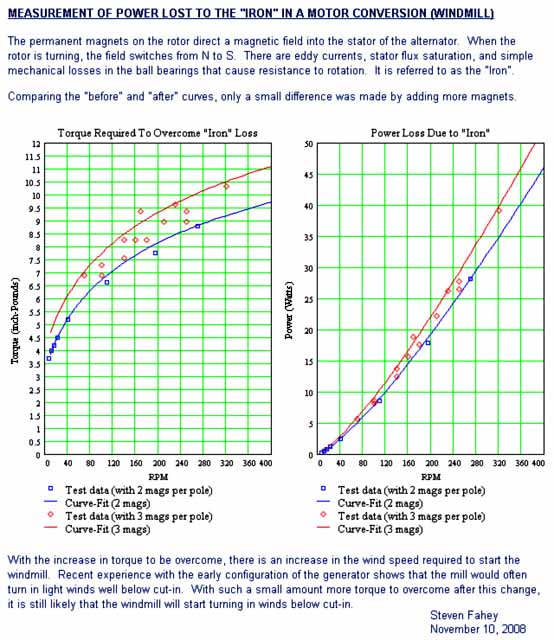

With the generator taken off the tower, I had an opportunity to make an important change to it. I pulled the rotor out of the stator, and I put 4 more magnets onto the rotor. When I first built this conversion, I was convinced that the two magnets per pole were enough. I thought that putting on more would make each magnet pole larger than the coils in the stator capturing the flux, making the AC waveform messy but adding no more power. Indeed I knew that it would cause more drag if I put more magnets on - more magnetic flux drawn through the stator iron laminations as it turns is yet another loss, and it's an important one in motor conversions.

Since building the GE conversion and raising it up last year, I have seen it perform reasonably well - 300W at 12V and 400W at 24V before furling (which was early, as I said). In search of more power, and reviewing my notes from last year, I decided that I would live with more iron resistance if I could capture more power by adding more magnets.

The magnets went on rather easily, and I still had the stainless steel screws I needed to hold them down. Reassembly went quite well, and the first few turns by hand gave me hope. There was obviously more resistance, but still not too much. I set up to test the motor to see how much it had changed. By pulling with a spring-scale, and tracking the RPM's with a bike speedometer, I re-created the test I performed 2 years ago. I have plotted the results of both tests on the same graph.

The iron resistance has increased, but much much less than I expected! It may be that this iron resistance has more to do with the change in flux from one pole to the next, than with the size of the pole itself.

I'm also pleased to see the open-circuit voltage go up, too. Before the change, the prop and generator were not matching up very well. The only connection that was working was Series-Delta, where I could get a 150 RPM cut-in. After this change, I can have virtually the same cut-in, but do it in Parallel-Star, which will give me more current.

Before putting everything back together again, the prop got yet another coating of linseed oil. The cedar blades have weathered (see my "rain erosion" posting from the summer) and need more TLC than I think I can give them. Another set may be in order next year.

It's all back up in the air now, and today's the first wind it's seen since the weekend. It came as a bit of a surprise, in fact, because the "wind" was more of a "breeze", yet suddenly the ammeter was waving between 3 and 6 Amps. Looks good. Next we need a gale to come along to test out the furling!

Steve