I've set up a new test on the bench.

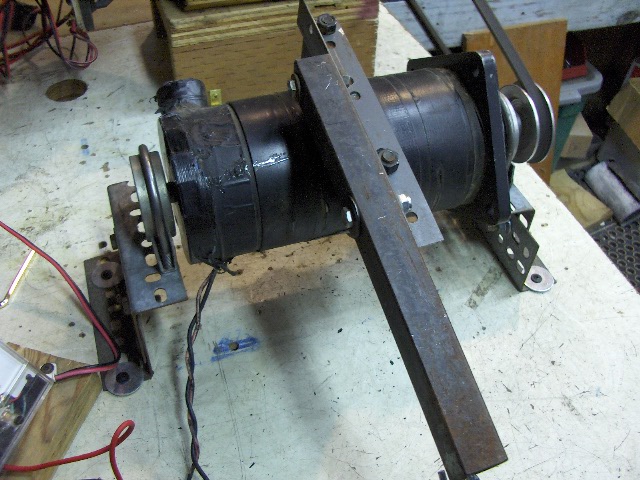

This time I'm using a 260 volt PM servo motor.

I don't have any other specs on this drive motor other then its 5" diameter and 12" long.

It has a 5/8" shaft protruding from each end.

I've mounted a bearing and support mechanizem at each end.

This alows the motor body to rotate freely.

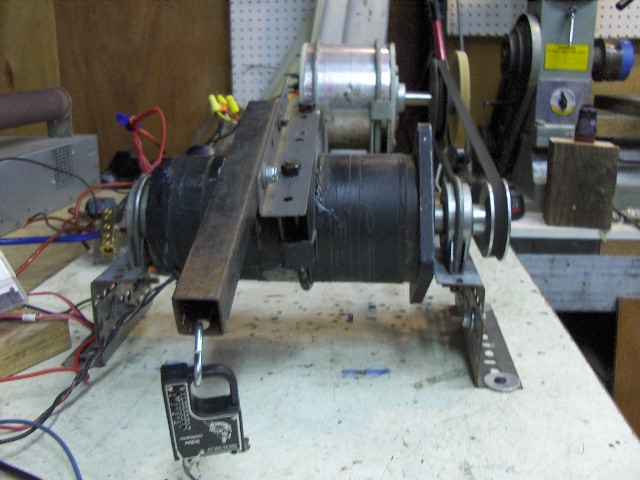

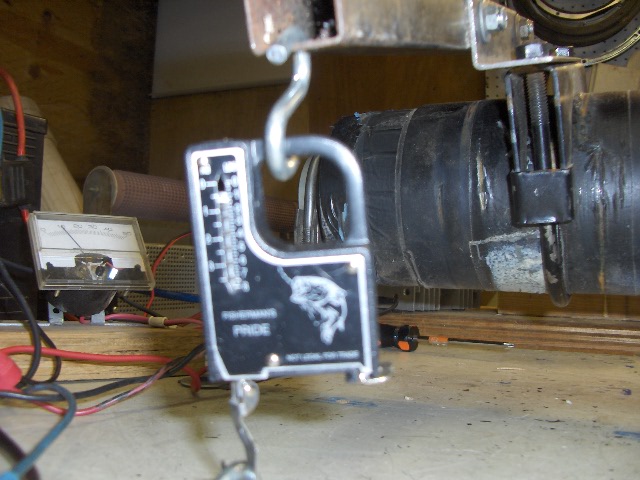

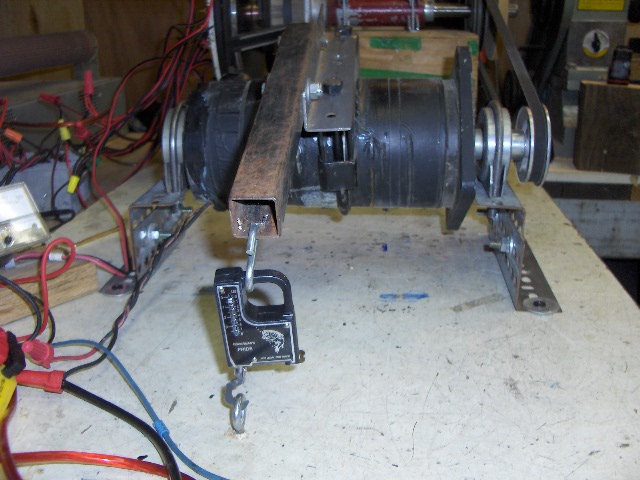

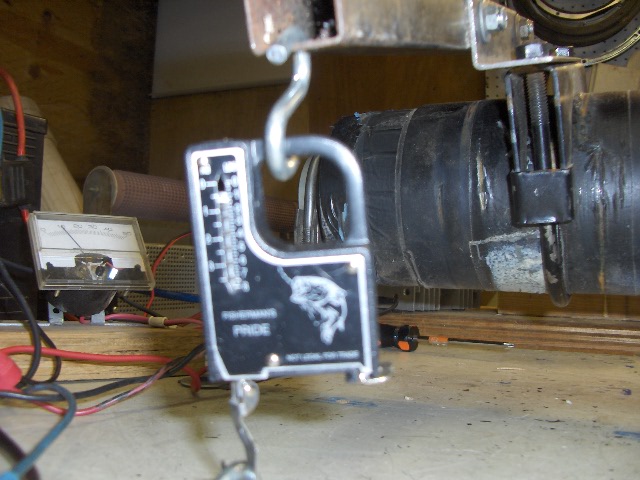

This could be a problem except I've mounted a bar to the motor body. This metal bar alows me to atach a small fish scales between it and the base that complete test assembly is mounted to.

I've also added an amp meter and a volt meter directly to the drive motor armature.

The fish scale shows the amount of LBs depending on the load on the motor.

A couple more pictures.

Heres what I mesured.

Hughs 4 ft PMA Drive motor

Amps to battery rpm Amps Volts Watts Fish scale reading

2.5 367 1 75.6 75.6 0 LBs

5 428 1.5 90.6 135.9 .5 LBs

7.5 469 2 100.4 200.8 .75 LBs

10 561 2.75 121.6 334.4 1.5 LBs

15 704 4 157.4 629.6 3 LBs

Garbogen PMA Drive motor

Amps To battery rpm Amps Volts Watts Fish scales reading

2.5 432 1 86.9 86.9 0 LBs

5 492 1.2 101.1 121.32 .25

7.5 546 1.7 113.9 193.63 .5 LBs

10 624 2.2 128 281.6 1 LBs

15 725 3 155.6 466.8 2.25

I don't know guys? It still apears the disc rotor machine requiers more power to operate at the same output.

I don't know if this is a good indicator or not but it sure apears that way on the surface.

Again the wind tunnel test will show the diferances.

The no load test were identical.

JK TAS Jerry