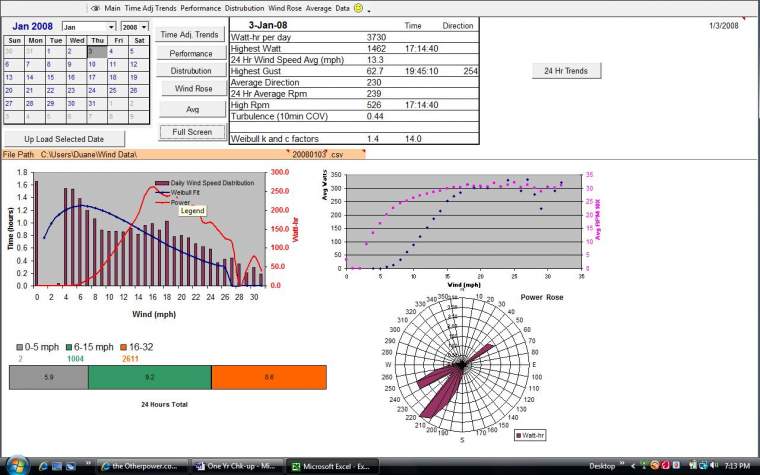

My wind turbine has now been in operation for one year. Overall the machine fared pretty well. The system was left to run through the winter to gather data and put the system through its paces. The highest recorded wind gust was 63 mph.

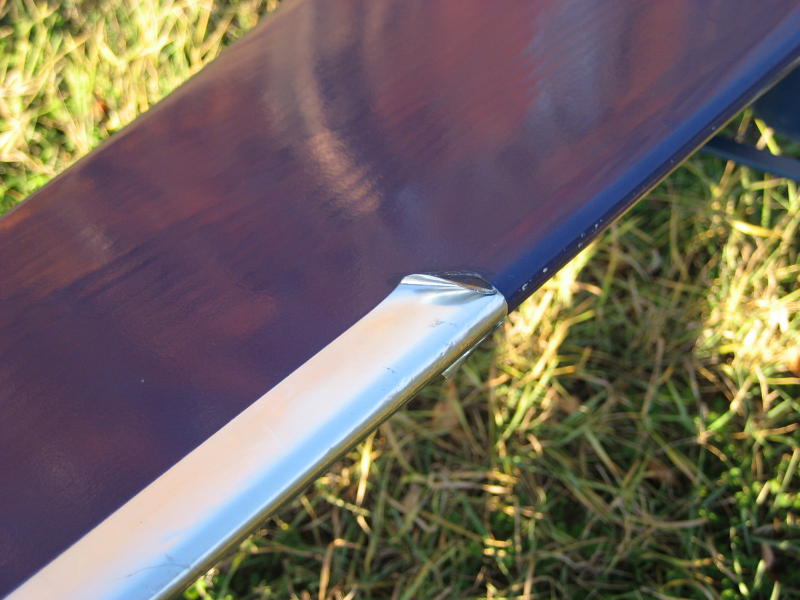

The stainless steal tape on the leading edge of the blades works well protecting the blades The tape ends began to peel up slightly at the corners. Before lowering the turbine, I could hear a low whistling sound, most likely caused by the tape pealing at the corners.

There was a little play in the rotor bearing. The gap between the stator and rotor was great enough so no contact occurred. Removed the prop and discovered the castle nut loose against the cotter pin. Tighten the nut one notch took all the play out. Although taking up on the nut made the rotation of the rotor a little snug.

The stator should no indication of overheating, not discoloration.

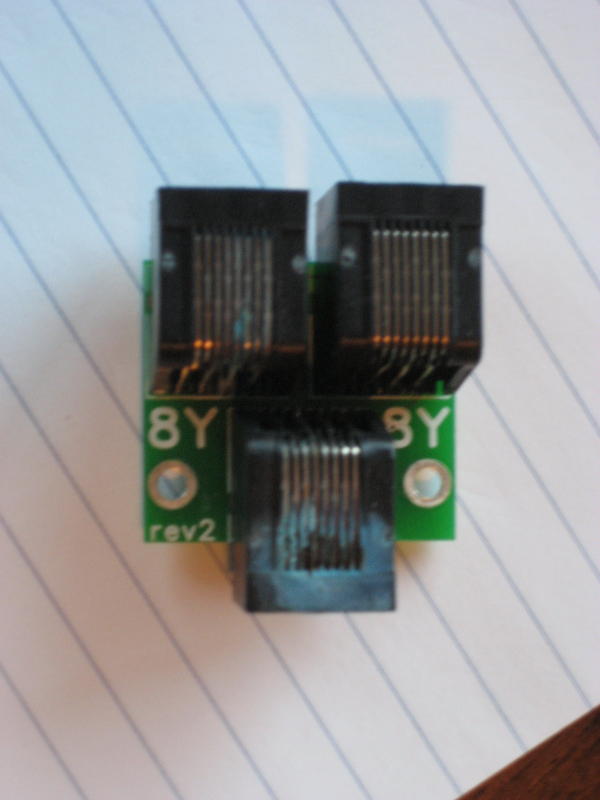

The split connection used on the weather station communication cable became corroded. It was replaced. The signal from the weather vane and anemometer was restored. This time the connections were sealed with dielectric silicon. Special thanks to APRS for sending a replace next day air.

max size for photos on this board is 640 x 480 pixels not 800 x 600 keep that in mind in the future please

Kurt