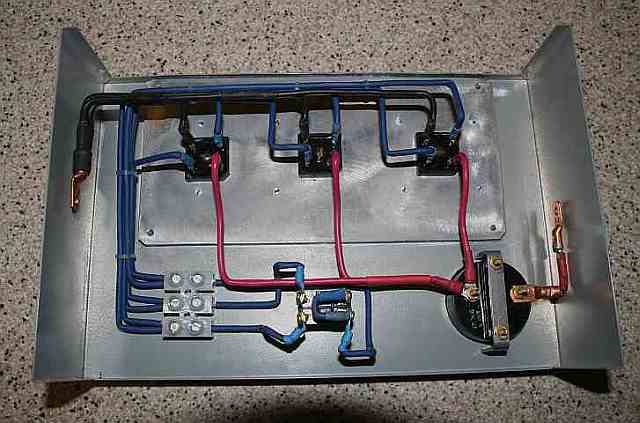

As it is so cold, and no shop heat, my wifes kitchen island became the work

shop. Built two rectifier assemblys. Have acquired hubs/spindles, SS

allthread/nuts, and a few other goodies.

I was a little worried about the size of the heatsink I used, so used a

piece of 1/4 inch aluminum behind to help spread out the heat. Will

post more as I get it done.

bj