Hello RE-group,

My latest crazy mini-mill project is something I have been meaning to do for a long time-- to make a small mill that is practically invisible even if it only makes low, consistent power in a low turbulant location. (goal is 20-30watts max)

I do not know the power yet--still waiting on some decent wind. If it works decent, I will call it the 'INVISI 32X Downwind turbine'.

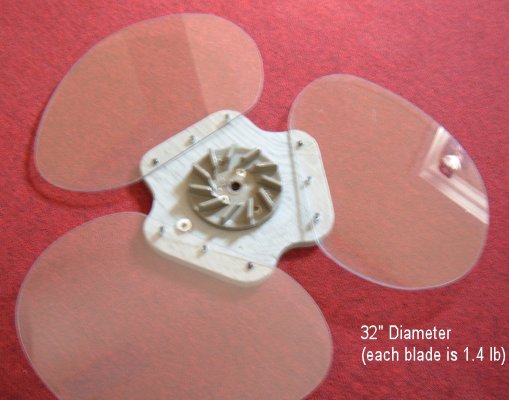

The blades are made out of very tough Polycarbonate. It is totally different from that brittle plexyglass. This stuff I couldn't even break with a hammer or snap it. They make tractor shields and machine guards out of this type of polycarbonate Lexan. It machines easy too. All's I could get was the 3/16" thick, so the blades are a little heavier than I would like at 1.4 lbs each.

The rotor with blades is 32 inch diameter. Not much swept area I know, but at least it is silent and not noticable.

Here is the first video with it going slow in a little breeze (I am standing on the peak of my roof):

http://www.youtube.com/watch?v=Wh3z2Efj4Jc

Sorry for the wind noise-- I forgot to put on the filter. I sound bummed out STILL waiting for some decent wind for days!!

Here is one more video with a little more wind-- feels about like 10mph but still to slow. The treadmill motor was just barely reaching a 6v cut-in (actually about 8v)making a couple watts so far.(probably only around 240rpm)

I need more wind!

http://www.youtube.com/watch?v=ykKVaVDAoZE&feature=related

The treadmill motor is only temporary while I finish the small alternator. I needed to see the rpm and behaviors of these flat blades before I can get any rough idea of the coils I need to make for the stator. The mag rotors are already done. (its a 8/6 dual mag rotor alternator)

So far, the blades SEEM to be somewhat slower than I had hoped, but they do have quite a bit of torque feels like.

For the testing of these round slower high solidity blades, I just screwed them to treated plywood with screws and used nuts to angle the blades. The blades look to be around 7 degree angle, but its difficult to be precise. If the project works out, I can weld up steel brackets instead of plywood and it should be even more invisible.

I'm not sure the static balance is perfect either. The oval shape makes it difficult.

I wonder now if a semetrical elongated round shape would be easier to be more certain of perfect static balance.

One good thing about these slower, high solidity blades is they turn (YAW) this DOWNWIND mill very effectively into the new wind direction when stopped. (Unlike my last Downwind mill)

The big blades gets over the motor cogging easily even with the small diameter.

I have no idea what it will do in very high winds since there is no furling. I hope it holds itself back. If it don't -- I can kiss the blades good bye since the high resistance motor will not hold it back by shorting. We'll see.

I will soon see just how fast it can go-- and if it holds together. I hope it will go up to 600rpm without shaking or becoming violent. I realize these small mills are just as dangerous as the big ones, so I will certainly be far away believe you me.

I believe I can also possibly bend the polycarbonate blades with a wood form and my heatgun into a graceful curve shape to reduce drag in the back side. (if I understand that correctly)

But I am not sure how much better that would increase the speed and power though.

Anyway I think it looks really neat and it is exciting to try to make the first almost invisible windmill.

I will post again if and when I get some power readings and when I make improvements.

Any comments, questions, or constructive advice would be much appreciated.

-Thanks!