Dear All,

I am hoping that I might be able to seek a bit of assistance from those what know?!

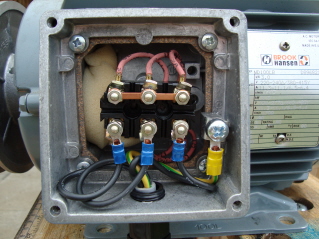

I have been working on a Brook Hansen 5hp conversion, with much support from others, thanks G-, Sparweb.

I have managed to get the rotor cut down and 20no N50(alledgedly) mags installed, 4 pole.

My next stumbling block is blade sizing, I usually opt for the trial and error approach as I am afraid I really struggle with anything maths related - having read the likes of Jerry and Zubbly it would appear I am going to be looking at carving some fairly sizeable blades? I can foresee stall as being a potential problem

Name Plate:

Motor:

I have tried to gather some data in the hopes it might help make a more educated guess than my normal methods (please excuse my terminology if it is not correct):

Open Voltage

VOC

RPM V

- 13

- 16.4

- 20.5

- 23.3

- 27.1

- 30.1

- 34.1

Into 12v battery

RPM V A (meter set 200m) A (meter set 10A)

- 12.9 0.3 0

- 14.1 6.4 0.34

- 17.1 15.5 1.17

- 17.7 23.5 2.29

- 18.8 36 3.33

- 19.9 48 4.51

- 23.2 61 6.42

- 10.73

I have not touched the internal wiring of the coils. Six wires out, removed jumper and connection block only.

I am trying this one as an experiment and my goal is to use it to charge a 12v battery bank. I was given two of these motors so this is really a learning curve for me - just hope I have not bitten off more than I can chew!!

I hope this info will suffice but please do say if more is required.

Many thanks in anticipation all.

Adam.