This is a 18 coil stator, two in hand #15 mag wire with 75 wraps. The stator will be 5/8" thick. I used a combination of 3/4 MDF, and 5/8 " plywood. I use melted toilet bowl wax brushed on for the release. I think if I did it again, I would use melted candle wax, because it sets up harder, and would not become imbeded in the bottom layer of fiberglass cloth. the first picture is the 1st phase of 6 coils in place.

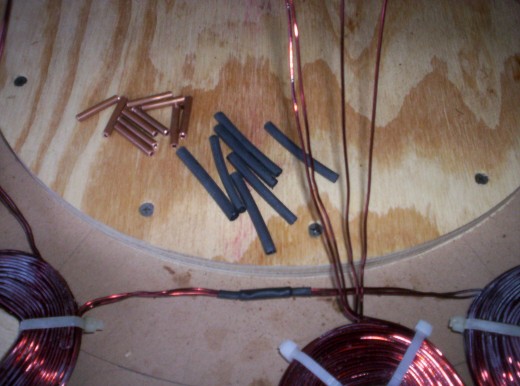

This is the way the conections were made, using 1/8"copper tubing, shrink wrap,and sodered. I think Dan or someone came up with this method, which works very good.

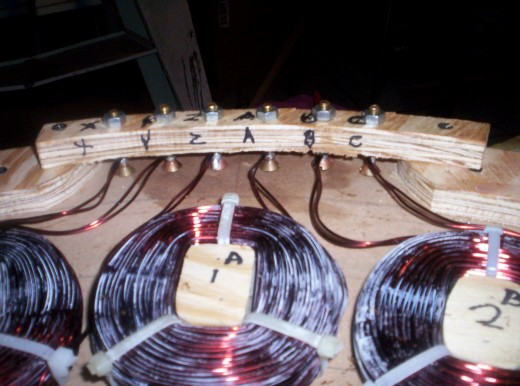

This shows all three phases in place, and oh yes, I used plywood blocks the shape of the inside hole of the coils which I think is good for two reasons, to help cool the coils, and also more important to keep all the coils in exactly the place I want them to stay, due to haveing to remove and replace during the pouring operation.

Close up of the star delta conection, using brass screws drilled for the wires, and sodered.

Here I used some of the waste plywood from the stator form, and wired it to the plastic ties that are around each of the coils, so that the whole unit can be easily picked up and put aside while installing the bottom cloth, and put back in. I put the coils in prior to pouring the resin. I than poured in about half of the form, and used the plywood ring to lift the coils alowing the resin to flow under, and than removed the plywood ring, and completed the pour.

This just shows the coils removed from the form.

Bottom fiberglass cloth in form.

The rest of the operation is pretty typical with what has been shown on this site, so no need to show anymore, The stator removed from the form very easy, and was satisfactory in my mind, of course with a few small bubbles.Any comments or questions appriciated. Harrie