Hello again friends:

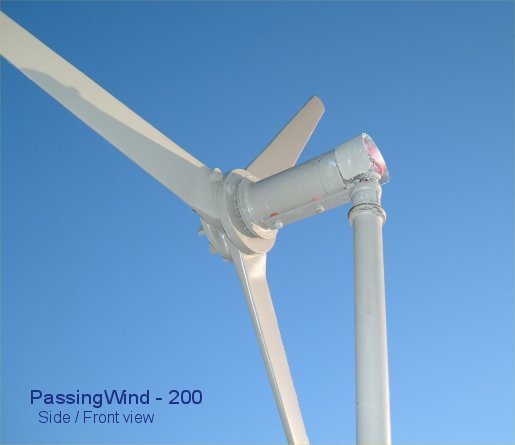

I am still quite the beginner, but I finally got my 4 foot radius treadmill motor / generator in the air last week and it has been exceeding my expectations. I named it the PASSINGWIND 200X.(ha!) It is the first generator I've ever got up in the air to actually generate serious 12 volt battery charging, so it is very exciting time, and i've been learning alot. There is alot to this story with many many pictures, so i will have to do the second part tomorrow night. First of all, i made this generator out of the $9.95 treadmill motor that has been sold in the 'SURPLUS CENTER' catalog for years. It is rated 260vdc @5 amps and 5100 rpm. My calculations were correct and it makes a VERY nice 12 volt charging DC generator. The blades 'cut-in' at about 320-350 rpm , which is nice. These are also the first blades I have every made using a typical $2 2x4. I followed DAN B's blade making page. Tomorrow I will show photos of that. This is, of course, a DOWNWIND type generator i decided to make first because I love the look of them. The coils are such big Gauge that I decided to forget furling and risk going all out with the wind and see what happens. Theres no way it will burn out and the ball bearings are big and tough,,so the worst thing could happen is to throw a blade.

It starts up with about a 12mph small wind gust and still generators down to 10mph, i am quessing. (I don't have a wind meter yet) I have gotton over 200 watts during that extreme 50MPH+ wind day last week and another one this week. However, that was quite scary cause I had just put it up. There was Zero wind (as usual) the first day I put it up--and then the next day was a hurricaine like day! But it survived even without guy wires even though the 50mph gusts were banging the pole around. I realized then that I MUST have guy wires even if they don't look good!

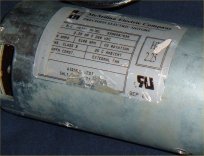

This is one of those surplus treadmill motors. (I got a few of them. It is rated 5 amps. The label is worn on this one)

I painted the heavy, balanced fan spindle in this photo.

Notice the rubber washers for mounting to reduce vibration and noise. I also had to balance the blades (which was easy-I'll show tommorrow) with washers.

This is where I wired it up and secured the wires with a hose clamp. I welded a piece of 3/8"rod to the fitting. There are 3 wires 'cause I plan on putting up a 3-phase machine over the summer on this pole. The main pipe is 1.25" black pipe--and the pipe that fits nicely into the main pipe is the 1" black pipe. I got the whole main 22 foot high black pipe (a 12' and a 10') for only $5 at steel salvage yard. Can't beat that with a stick! The fitting is welded to a piece of 1/4" steel (which i hardened with my propane torch) , and then that is (epoxy)bolted to the generator. Also ,the threads of the fitting is epoxied to pole, and tightly screwed on with pipe wrenches. I had to break this loose once 'cause I forgot to put the stinkin 8ga. wires up thru the hole of the fitting! Boy was that really on there! You can see the marks. Lastly, I greased the pole good with typical marine grease.

I hope I'm commenting on the right photo cause it gets confusing. I think this is the close up of the back side to show how I mounted everything. Simple staightforward yaw axis design. There are two big washers inbetween.It turns great in the wind directions.

This is a good picture of the hight of it. It is close to 23 feet in the air and about 8 feet above my roof line.

Here is another far away shot. The blades were actually spinning 800 rpm but my digital camera makes it look stopped. Nevertheless, I painted it the color of treebark so it would be less noticable. I like the color.

The power it produces goes up and down alot. It constantly goes up and down all day long since it is only alittle higher than my roof. On a decently windy day (15-20mph) I see 5 amps and more quite often. On a very gusty day like 30mph -50mph gusts, i've seen it go up to 14 amps at 15 volts! But the blades must of been going nearly 2000 rpm!! I'm not Totally sure- I'm still quite the beginner. Nevertheless, it has been one heck of an exciting venture!

Much thanks to DAN B and friends and everyone here who was been helping me with all my many questions! I'll do Part Two tomorrow night ,cause its late and i'm sleepy.