Flux,

whilst I understand your argument, your conclusion does not seem to be born out in real world testing.

These graphs would seem to indicate that a vast improvement for wind application is apparent with this style of high pole count alternator.

Here is the data of relevance as explained by the experimenter

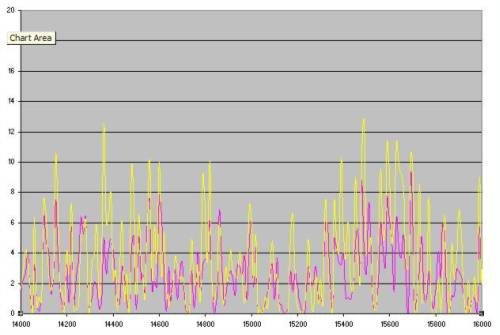

"This is a comparison of before and after series caps on a 100S F&P in delta.

The comparison should be interpreted as the change in the ratio of the average of the F&P in yellow to the axial flux in purple. The F&P has 50% larger swept area.

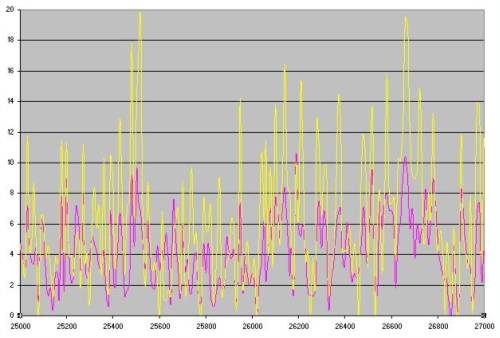

Thge first graph is before caps with maximiser and the second shows the change in the yellow graph[F&P with caps], without maximiser. The ratio of the average of the data is the important detail."

"The ratio in the first graph is 1.33

The ratio in the second graph is 1.46

The caps provide a better increase in average power than a boost maximiser.

There is a significant increase in the maximum power output, by almost a factor of 2. This would be of more use in stronger wind conditions.

A combination of capacitors and boost maximiser will be looked at next.

This should give benefit at the top and bottom of the windspeed range.

More to come.

Gordon.

PS

The graphs are battery current vs time, for the same timing period. The wind conditions had changed, but the 2 windmills were operation in the same winds, with no wind shadowing and are only 6m apart."

===================

The yellow is the F&P, and the pink is the axial flux alternator used as a reference.... 6 meters apart

Faced with this result, I think your conclusion "Not really practical for wind but it may be a useful dodge with hydro where you run at constant speed and can maintain resonance." is difficult to comprehend.

I would have thought an increase of that magnitude is worthwhile, and would certainly be applicable to wind. It also seems to stop the mill going into runaway at 10 or so amps... which alone is very worthwhile.

It seems to me that getting some improvement in some parts of the spectrum, and massive improvement in other parts is worth pursuing, stopping runaway and getting a vast improvement in power where non at all was available before (because of reactance limiting at 11A) is a worthwhile gain, The caps seem to turn a very average device into a reasonable device.... (I'll stick with axials myself however)

........mystified with your conclusion here

........oztules