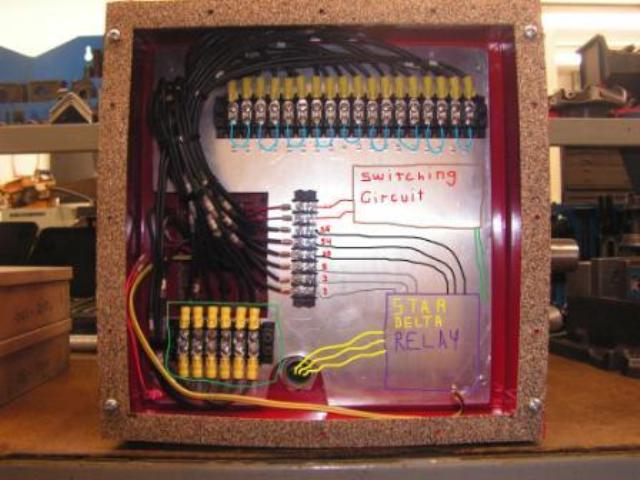

I have mounted a box on the side of the baldor/ rewound gen.

Is it a triple pole triple throw relay that I need to find for this to be able to switch from star and delta and not use individual relays as they may cause a problem?

With peaks of around 4kw, as far as current and voltage go what should I be looking for in a relay?

Any help here from Zubbly as I know this is what you have already been working on, what kind of circuit would work for switching the relay on and off.

Along with rewinding the baldor I threw in 3 extra coils of much smaller wire that could provide power for some kind of switching circuit. I tested voltage on these smaller wires as well and here are some of the results.

64.2 volts at 654 rpm

44.6 volts at 494 rpm

33.7 volts at 351 rpm

21.7 volts at 256 rpm

11.2 volts at 132 rpm

8 volts at 95 rpm

These numbers are with all 3 coils wired in series, so if the voltage is too high I could use only 1 or 2 of the coils or possibly parallel them

Maybe even use 1 coil for a trigger, or sensor for rpm some how if possible. I have looked and found some possible circuits on this board but not really sure which one would best suit my needs.

Would a circuit run on variable voltage with use of a zener diode to limit the voltage or would that not work?

I could run only 3 wires down the tower if I could get all I need in this box for switching star and delta

to simplify connections I used these terminal strips, for 1,2 and 3 star or delta I would always leave the wires in the lower left outlined in green just as they are. Other connections would be changed at the lower side of the top strip and the strip in the center.

lathe testing being done at different rpm's no load