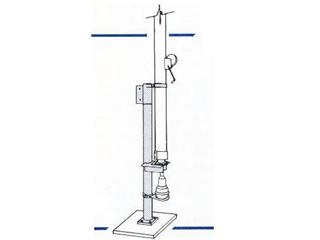

Most of the time a flat plate is welded to the bottom and holes in 4 corner that go to threaded rod that is bent at the bottom so it can't spin in the concrete. Nut, large flat washer, tube + plate, large flat washer, lock washer, nut... can then use a level on each side and adjust the nuts until level. Then pack in high compression grout under the plate to stabilize it.

Example, this held a 45 foot rotating tower with the rotator mounted on this. I used to own one. The base was 4'x4'x8' deep, the threaded rod was 3/4 inch and 5 feet long.