Hi Norm.

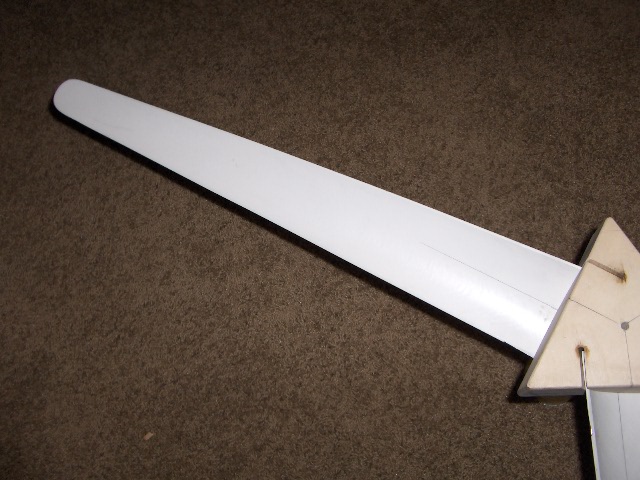

I'm in the prosess of trying my hand at the PVC pipe blades. Today I assembled a 4ft set.

This first blade set is made from 6" diameter 1/16" thin wall pipe. I'm using a hub made from 2 pices of 3/4" plywood laminated for a 1.5" thickness.

The hub is tryangle shaped. I used an 1/8" wood cutting blade on my Roto Zip with the circal cutting atachment set at 6" diameter. I cut a groove on the side faces of the tryangle to set the blades into. Then I drilled a screw through the hub and blade to secure the blade.

This is just a test blade to get the feel for this design. I'm building another the same way but with 6" diameter pipe that has a foam core and is 5/16" thick. The core stuff is very strong.

I'd say with the curve of the pipe it may be stronger then wood.

After I finished the thin blade I took it outside. At this point there no shaft hole yet, just the 1/4" hole in the center. I put a bolt through the hole.

There just a very slight wind 2 to 4 mph maybe. The blade began to spin to a point I was getting a littel nervus.

Its 28 degrees at the root and just a few degrees at the tip. I think the cup of the blade at the root makes for good startup tourque and the small tip zings through the air with the greatest of ease.

Here a couple pictures.

JK TAS Jerry