Saturday was the day when it all finally came to gether and I got my firsy build up in the air.

I have no means of welding, so the whole thing has to be bolted together. The chasis is a nice thick block of aluminum, its nealy an inch thick by about 4" wide. The main rotor axle goes through a threaded hole in this block. The stator is supported by a round disk of some strange plywood that I found; it's hardwoood ply, sandwiched between 1mm aluminium. Strong stuff and very light, the diskyou can see is painted silver to selathe edges so lookslike solid metal.

I made a three phase rectifier out of stud diodes, this is bolted to the back of the plate housed in a little box. There is a heatsink on the box lid, but this is mainly for show as I doubt I willever see enough power to get it that warm!

I've made a furling tail usin a standard door hinge, but mounting it at an angle. The angle of the hinge on it's mount is around 20 degrees, and this plate can be mounted at afurther angle to the aluminum block. I haven't done the calculations, but everything is adjustable, and I can tune it later. Those same green mounts are on the tail vane, so it can be slid along the tail bar.

Here you can see it fitted....

and furled.....

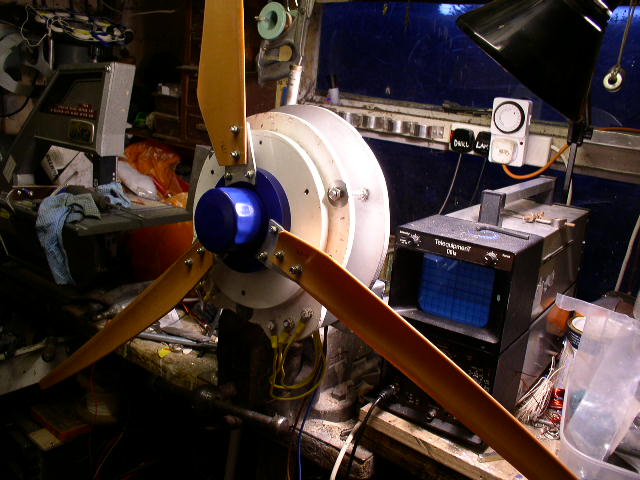

Here are the blades fitted to the rotors. The blades are mounted to an aluminium ring boss (blue) and held to the rotor by six bolts coming all the way through. See earler diaries for details. The nuts are under that blue dome which if a cut-down GM cartidge oil filter.

This is my son Steve (Chip Slog) making some adjustments before we mount it on the tower

And here he is again making the connections. The tower is a piece of scaffolding tube attatched to the tree house. There is a shaft with bearing going down into the tube. You can't see it here because it's top if flush with the woodwork, this turbine will be raised vertically by winching up the base of the tube.

When it's up it looks like this.

It will go higher than it isat the moment, and it will creep up there a bit at a time over summer so as not to frighten the locals!

So far, I'm not getting a lot of power, in fact almost none. I have it hooked up to two very small 12 volt batteries which power some garden lights, and I see hardly any charge current. I did have a car bulb (21W) on it at first just for braking, and when I connected this when it was spinning quickly, I managed to blow the filament. But it won't light such a bulb in the wind I have, the blades are not upto the job. They are about 3' 8" diameter and don't have enough twist at the root. I'm planning to put 4.5 feet blades on, and mount them for a bit more twist.

Thanks for looking.