While going to machine shop today I thought,

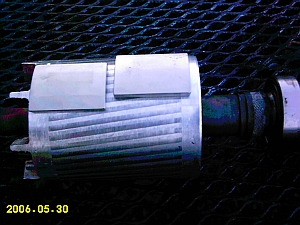

Hey, why not take the other two HP 3 phase along for

getting them trimmed down for Magnet placement?

??

So while still in the middle of the Baldor unit, I'm also

just as far along or more now with this 3 phaser.

While sitting there waiting for machinist to return from lunch,

I got to playing around with the case and a razor blade.

I figure they say it's across from the out wires,.......

So I dig in and with just a couple of carefuly placed slides of the blade,

I'm looking at what looks to be the "Star" conection, ...

Three wires all into one plug thingy, lol

Just need to drag it in from truck and check with multimeter.

src="http://www.otherpower.com/images/scimages/4993/Gould_Century_2HP_3Phase.jpg" width=80%>

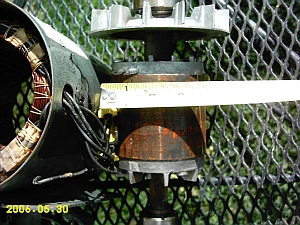

Rotor Dia. 3.225"

After the lathe work it's easy to see that they do have off-set's on the lam's.

What I'm wondering now is,.

Do I still need to off-set the magnets or will the lam's take care of it? ?

?

I quess I'll try to super glue and pop bottle shrink wrap it to test.

fixed your pic