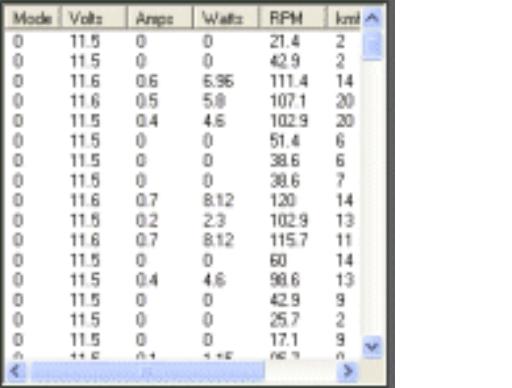

I cant make out your data ?

Your average RPM and average KPH dont match.

what i mean is line 4 & 5 , your average max air speed for the particular data set shown (20 kph ,12.4 mph ),does not correspond with your average max RPM line nine.

It may sound like i'm nit picking ,but not at all. i just think that the numbers should correspond , and it would bug the crap out of me till they did match.

if you sampled the wind speed more often that may help a bit.

also you need a better match between the alt and the blade set , because your mill spends most of its time not producing any power .

if it could produce power in the 6 mph range(9KPH), that would help out a lot , it may be as simple as making your blades a little smaller ( more rpm) , or adding another three coils (one per phase) , not the easier of the two choices..

have you got a photo of the blades per chance?

i am very jealous of what you have done so far , keep up the good work , some day i hope to have a similar data logger for my blades , but i need one more piece of data , torque output of the blades vs wind speed and rpm.