It took a week to put it all together and another to get it dialed in ( as well as learning how to run it). It's up and running! I still have a couple more tweaks but it does a great job!

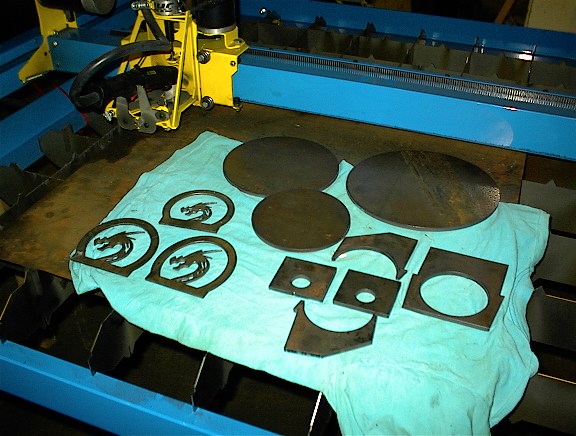

I can start finishing some long awaited projects without waiting for parts. The brackets on the lower right are for a tower pivot assembly that I bought the poles for 3 years back but didn't want to spend the money to have the brackets lazer cut. They charge a fortune for "one offs".

I can cut up to 1/2" plate but I can't handle loading that in big sheets. Most of what I'll do is in 1/4" and less with an ocasional 3/8" small plate when I can find them.

I picked up a magnetic lifter to load a 4ft x 4ft 1/4" plate on the machine using my cherry picker and it works great. Loading a 170 lb plate is a bit much for me to man-handle.

I'm still learning the machine and software but so far I haven't found anything I couldn't make and cut.

If you have a program that will save the drawing to a dxf format I can import it into the program and cut it. I use Inventor 5 for big projects from drawings to assembly but for basic 2d stuff -( quick parts )- I use Quickcad which is a low grade spin off of autocad lite. Let me know if you need anything, I can do one offs at a reasonable price.

The only thing I've noticed is it cuts holes at a slight taper, the smaller the hole the more taper. As well, the thicker the metal the more apparant the taper will be. Just a matter of running a drill through it to size it up which is fine.

Lots of fun!

.