Awhile back I posted I was trying this motor as a 6pole 6pole and cogging terrible, needed a wrench to turn it. Sorry I am not keeping up on things, lots of stuff going on here but getting better now.

So last night I worked on this motor a bit. It was suggested by Jerry that I use 4 poles on the armature instead of 6 to reduce cogging and then seperate the coils. I did this last night it works far better but still alot of cogging.

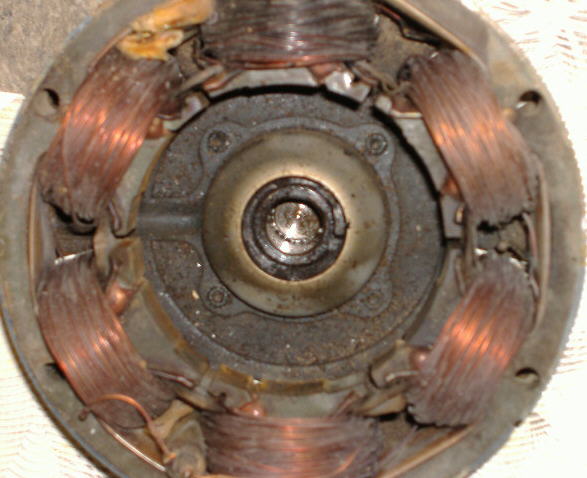

This is what I have now, but not new pictures.

I took out the burnt coil, was 160 turns there give or take my mis-counting if any.

I broke each coil into a seperate coil and let the start and end dangle loose out the back of the case. Then I made the armature up of 4 poles, 1/2" disks, 4 disks to a pole like this,

That is the old 6 pole picture, but I made the poles the same, about 90 degrees apart.

When I put this back together then as 5 seperate coils it turns far easier than it did with 6 poles, but the 4 poles still cogg allot. I put this in the small drill press, the slowest speed is about 760rpm so I tested 1 coil abit at 760rpm.

As it is wound now, 1 coil gives 5.4Vac open volts, bridge rectifier will give 5.4Vdc open volts. Short circuit amps was about 2.4 I think.

So I wired up some dead Ni-cad cells I had on hand for about a 4.8-5.2V load. These were DEAD like a string of four cells was 1.5V total.

At 760rpm one coil brought the dead cells up to 5.4V fast. I tried to get an amp reading and once saw well over 1 amp for a second then dropped fast to almost nothing.

I don't think the Ni-cads were enough load but was all I had handy for near 5V.

I won't be finishing this motor for while, I will probably rewind that empty coil pole with same size wire and allot more turns, then take it out and wire with heavier wire, 2 in hand etc.. and see what the one empty coil slot can do. When I find what I like best then I'll wind all 6 coils the same. I think this wire was about #22 or #24 but not sure. Lost my calipers while moving into the old trailer this last week.

I have a ton of #24, well about 20lbs or so anyway. I think I will re-wire with that 2 in hand first and see what one coil does. Lots of room for more wire in this motor.

The goal is a lower RPM 12V genny and reduce cogging a bit more.

Didn't get any new pictures of anything. I was working with a 5watt HF 12V CFL from the HF solar panel kit and it was hanging from the ceiling to see around the room dimmly.

My main work light was Reall Nice 11watt 12V CFL I got from Ghurd. I bought 2 of them but only using 1 right now.

For my work light, I cut the cord off a nice normal floor lamp I had handy and soldered on aligator clips. I clip the lamp to a 17amphr SLA battery and have Ghurds 11Watt CFL installed. So far the normal AC light switch is working fine, I must have turned it on/off a 100 times by now. This gives me a nice movable lamp right near where I am working and lights the room nicely also.

NTL