Where to start...The materials.

Yes,that's right,greengrocers crates.Absolutely FREE.

Maybe some of you reading this magic word are running to the greengrocer allready,but warning:this is a lot of work! No such thing as a free lunch.

Well never mind,this is great stuff for lighting the fire too.

Carefully taking off the planchettes,a knowhow by it's own.

Then sawing them to uniform strips(I did it on my small bandsaw),mostly 35mm for me.

They are mostly with rusty holes of nails,cracks,and nots.

The planchettes are mostly 2mm(2/25") and 4mm(4/25").They are in poplar(majority)and pine.These details are for France and may depend on local conditions.

I only used the poplar allthough they are very warped compared to the pine.I think ppoplar is superiour for this purpose,there must be a reason poplar was widely used in early aircraft construction.Light,soft,but strong(and cheap).Used in lamination,the warping is not a point.

This is the yield of 3 or 4 crates.Great basic material.I didn't use much of the 2mm this is more work and cost more glue. A shame there is not much of 6mm or more available.

This is the expensif stuff.The 13.30 Euro is for 500 gram.I used about a half of these flacon for what you get in this diary.I have a love-hate relation with this stuff.By principle I hate chemical stuff,but I don't know about anything comparable for wood.It is very water resistant and strong with an axcellent adhesion.

It's foaming and fills up small cavities and cracks.

Here you see the foam coming out of laminates.

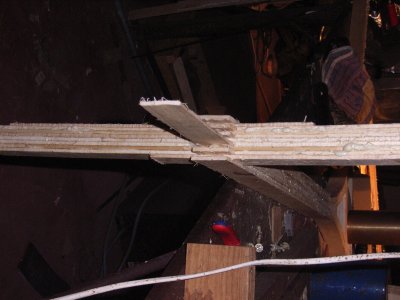

I started gluing together some,

Then it started growing,layer by layer,a bit like a tree.

Allways lots of clamps

vertical arms for the future airfoils in progress

Then I realised I needed a hub

I made it fit in the center,then machined the two surfaces.

This was my first mistake.The hub was were I should have started˙Ishould have machined it on the circonference,and then start the rotor fitted on the hub.

Never mind it is not that bad.

some finishing.

Well,sofar

cheers,

Jaap