That is a good point Ghurd. New persons have to realize that the GREAT MAJORITY of Dc Permanent magnet motors and AC&DC servos on ebay are WORTHLESS as windmills. A newbie has to understand that only one with the correct numbers (voltage ratings, RPM, amps) will work decent.

I certainly did not mean to sound negetive. It is difficult to explain everything.

I've also noticed that finding usable good DC motors for windmill generators it getting more and more difficult to find a good deal on ebay.

You are right though, ac servos are probably the most difficult to know if they would make decent mills because they usually leave off the important numbers like the voltage ratings, and/or the rpm, and actual rated amps.

But sometimes you can find the info by searching the manufacturer on the web and get a great deal on one of the newer type ac servos with the NEO mag rotors and high amps. (many of the older, heavier ones used Ferrite mag rotors)

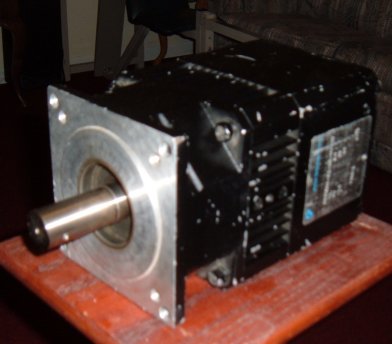

I did alittle research and got this brand NEW 'Pacific Scientific' ac 3-phase brushless servo recently for under $50 on ebay. It is less than one ohm of resistance.

This one according to the label runs (or; should generate around) 70v/ per KRPM.

or; 70v per 1000rpm //or; 7v per 100rpm) So 12v cut-in was exactly what I thought it was going to be: around 180rpm. I use the same BASIC 'rated volts/to the rpm' basic formula as we all do DC motors to calculate 12v cut-in.

This one is 13.5 amps and probably about 1.5KW rated as a motor drive.

The bigger the amps and KW rating the more power it should make as a generator.(IF the volts to rpm ratings are right)

The black paint chips off the aluminum easy. These new servos are normally over $2000 since they went on CNC machines. This one weighs only 30 lbs and has zero cogging, no friction from the bearings (a tiny finger clamp onto the shaft easily turns it!) , and it could probably do over 300watts in a big wind if I wanted to put a small 5' prop on it. (which I don't)

With my big slow drill testing, it easily did over 110 watts at around 400rpm with no bearing down on the drill at all. (Unlike when I tested my last 4.5amp 180vDC motor with the same drill which beared down quite a lot due to higher resistance)

Since it has a nice big inch and an eighth shaft, I am putting a nice 8' prop on it to do more watthours per average day in the lower winds of my location.

I must say from my drill testing , I like it twice as much as a normal DC motor.

Like you say, some of servos do have the brake that is normally 'on' and would need to be disengaged somehow. Mine did not have this.

For a newbie, it might be better to stick with the Ametek until they learn more.

These are tricky for new persons and hard to come by for a great price on ebay.

But I must say I like the big AC servo motors better than DC motors. But I STILL like my big DC motor mill too!

Of course though, the best thing of all is to learn to make a MOST efficient alternator from scratch as they show how to do here-- and you can know exactly what you're getting!.

I hope I throughly confused everybody!