Hi, first i want to thanks everybody on this board who given me this hobby and passion.

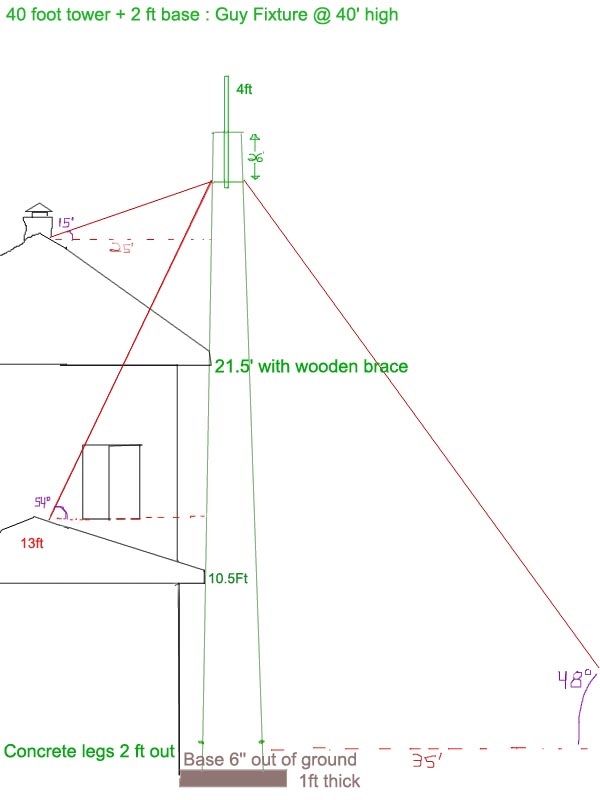

It been a while since i'm reading on the board. I'm living in town, but my parents own an isolated house with a 40 foots dmx tower that were used for tv antenna and large CB antenna (CB antenna as been removed, and Tv antenna relocated). I plan to put a mill (don't know yet the size) over the top of tower on a pipe. I'll probably be limited to 2 inches by the top plate, but i'll probably make thicker one with 2.5 inches hole. For that i'll probably take the section down since i don't like to be belted to something barely holding ...

I know that i'll hear vibration from the mill in the house.

Here are the specs of tower; http://www.wade-antenna.com/Wade/DMX.pdf

they state a wind area of 3 square feet for the 40' tower i'm working on.

In the guyed Dmx Specs; http://www.wade-antenna.com/Wade/CGTowers.pdf if i understood well, they state of tower going to 147ft with an horizontal wind load of 300lbs and an antenna weight of 80lbs. It use some bigger and smaller section that the one that compose mine; my two highest section are smaller than their one.

I'm on the way to design a geared PM motor with furling and if everything fail or fall  there will be on main blade shaft a centrifugal clutch that will begin to brake if the chain broke or furling mechanism fail. I guess it should be lighter than dual rotor generator.

there will be on main blade shaft a centrifugal clutch that will begin to brake if the chain broke or furling mechanism fail. I guess it should be lighter than dual rotor generator.

Here are some picture on the field.

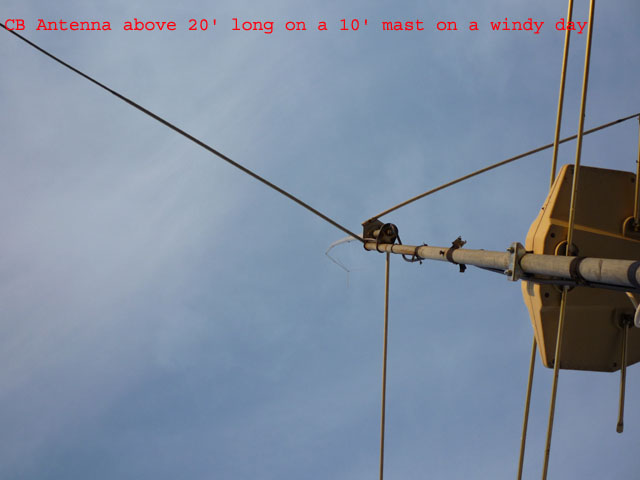

The wind was moving the tower a lot whit this large antenna. It's lightweight but take wind well. Now its removed.

Before any modification, it was looking like this.

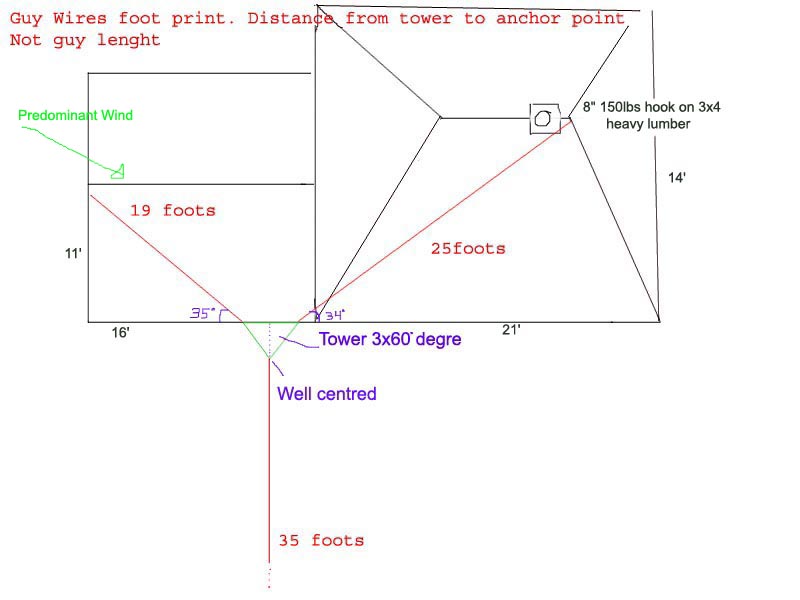

This is two plans with mesure for guy wires.

I'm currently using 7*19 galvanized wire. The 19 and 35 foot guys are 1/8. The one near of cheminy is 5/32. I did not find galvanized or hardened Turnbuckles so i used 1/4 turnbuckles. I used Thimbles everywhere a guy attach to something.

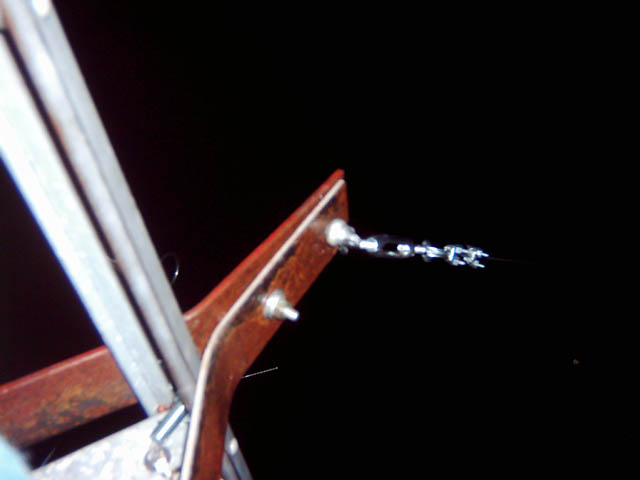

I locked my schackle with fence galvanized wire #16. My wire rope clips are made of cheap metal so i'll put Stainless one before putting the mill on top.

the 19 foot guy is on roof, but guy continue to the concrete basement where its anchored.

Reinforcement has been made on higher roof witch encouraged me to climb to large cb antenna.

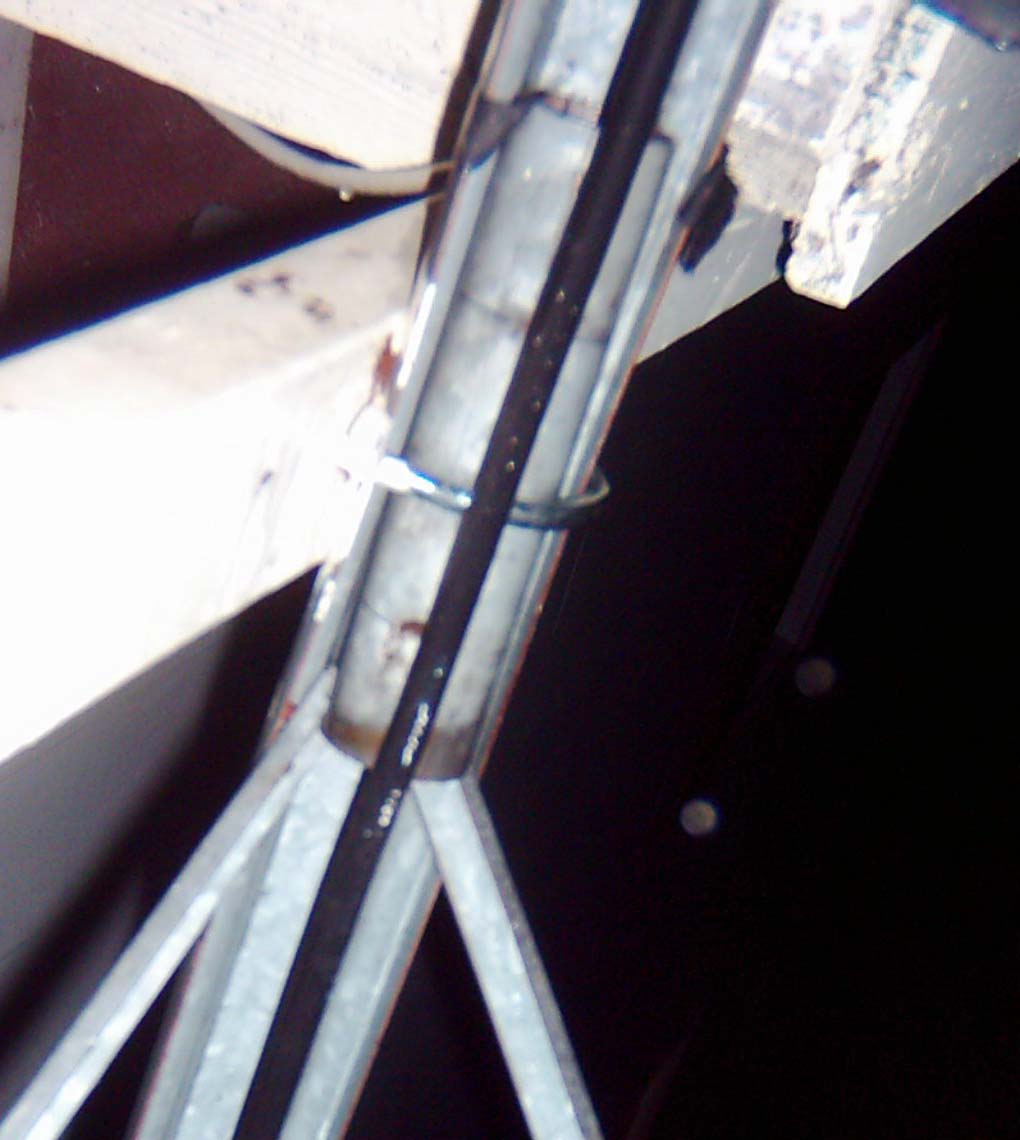

In this picture i put pipe in the tower legs to avoid bending, and put large flat washer with nylon lock on U-bolt.

So its looking like this,but now i have guy installed. The red arrow show where the tower is anchored to something.

I was thinking to use anchor points like this, but the load would always 'open' the tower's leg.

So I installed something like a collar that hold over the tower and take the 'expansion' load. the outgoing legs are also acting as stablizer like the real tower giving more strenght to counter twist.

Almost all therms and guys words came from http://www.baronsnaps.com to be well understood from the english majority of the board.

As i write this i realized that i should have went with 5/32 on top at beggening and i'll reuse my 1/8 to 30 foot. I'll do that this week end if experimented ones found it clever and enought strong.

Remember the tower is not intended to be tilted.

Now it's the question time !

- - Are the guys big enough (considering 5/32 top & 1/8@30ft)?

- - Is the mis alignement of guys wire of 4-5deg critical ?

- - What size of mill can i put on this kind of tower (guyed as i plan or following your experience)

- a What size of guy should i use if i plant to put a 10footer axial later ?

- - Are my standard turnbuckle a critical failure potential ?

- a- A ground wire is bolted on the lower tower leg to a 6ft rod, should i keep it ?

- b- Should i ground the guys?

- c- Should i ground the inverter in basement with main braker box ground ?

Before you ask, i consider climbing when its dark as almost normal, so i'm a bit sick in the head.