My 12 year old washing machine finally fell apart, and I

splashed out on a new one. While stripping the old one

for useful bits, I caught sight of the old motor.

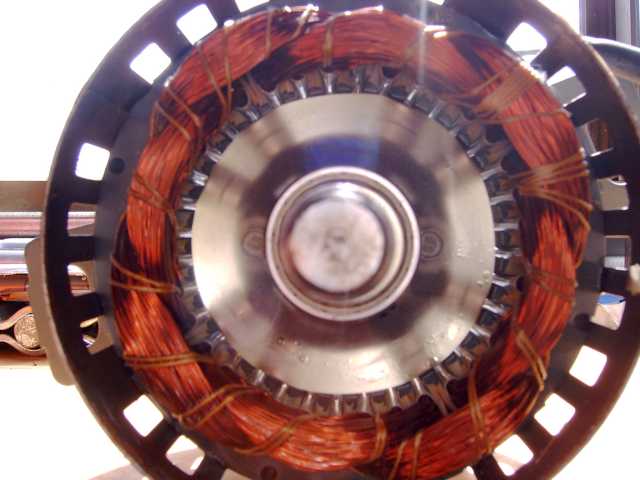

A quick check showed it was an induction motor. I'm in

Australia, so our stuff is 240VAC 50Hz. Although it had

no spec plate or even a model number, I estimate it was

about a 1/2hp to 1hp (~375W to 750W)? Seems to have a

4-pole 2-phase type of arrangement. It had a capacitor for

start/run on the second phase and a thermal fuse imbedded

in the windings. I bypassed the fuse to stop it doing anything

silly. This is a close up of the fuse.

The belt pulley was made of aluminium, and I will turn that

down in the lathe to become part of the blade hub later.

The rotor was about 80mm in diameter, and about 30mm

deep. I thought about buying some long narrow bar magnets

and skewing them slightly. But I remembered I had a pack

of 100 13mm x 5mm disk magnets. Although they are small

and fiddly, I got them for about AU$15 and stacking them

should improve the flux output.

This is what the rotor looked like after being machined down

and with the magnets stacked in a 3x2 configuration. I seem

to allow more space between poles than a lot of other conversion

people do, perhaps I'm fussy about cancellation in the waveform.

Here is a series of pics, where you can also see how I used the

roof screws again to stop the laminates from falling apart. Also

the magnets over hang the rotor a bit. I could have made a fresh

rotor but - bah, this is more of a toy for me

I keep all my old plastic, metal & glass containers these days.

They come in handy for so many things.

I sliced up an old juice container and wrapped it around the magnets.

Super glue joined it at the overlap. A plastic lid formed the bottom

of the mould, and good old silicone sealed all the gaps. You'll notice

I have not used a cage for the magnets. I want to push the new epoxy

to the limits

The rotor sat just nice inside the old juice container base.

Making it both a support and a spill container.

I bought some West System Epoxy this time, as I noticed a

lot of the forum use it. I'm using the 206 slow hardener,

as I'm a firm believer in a better cure for a slow cool/reaction.

This is my patented :-) epoxy mixing tool. As you can see,

it was not engineered on a CAD system.

I use an old 12V drill connected to a 50Ahr battery for mixing

the epoxy. It means you never go flat in the middle of mixing,

or any other workshop job for that matter :-)

Here is the rotor about 30 minutes after being poured with epoxy.

Most of the bubbles have risen to the top, and formed a froth layer.

After curing for a week in our tropical sun, I put the rotor back

into the lathe and cleaned up the epoxy. The silicone and old

plastic container bits were peeled off easily by hand.

Here it is with the sun behind it. You can see the magnets inside the epoxy.

It has two new bearings, and I added some welds to the

mounting ears to make sure they don't break.

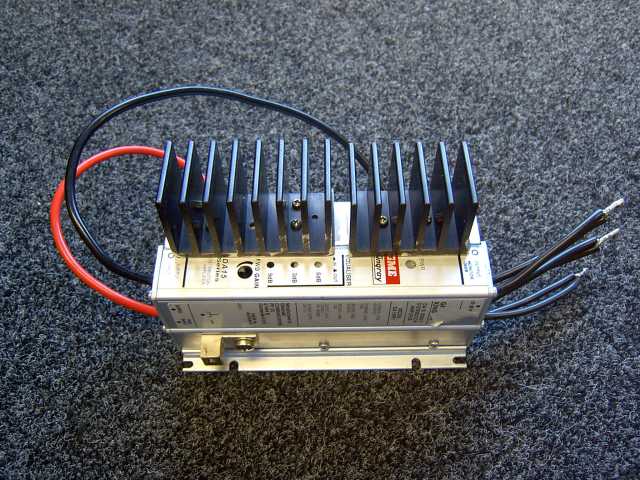

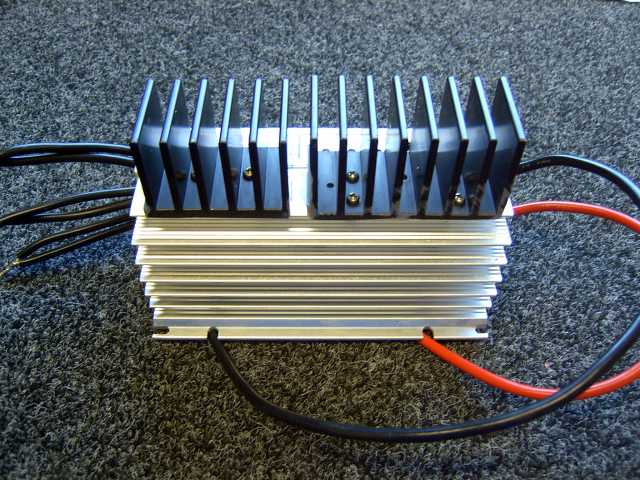

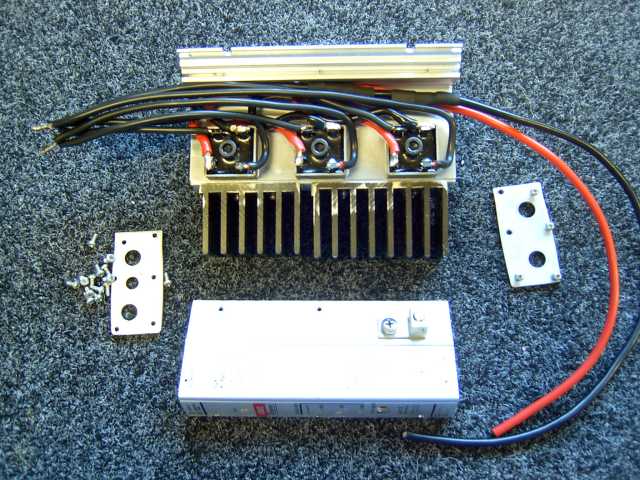

I used an old MATV amp to fit some 50Amp 600Volt bridge

rectifiers to. It was a good opportunity to play with the new

milling machine. I had to make a wider base for the bridges

to mount to, so a second MATV heatsink was cut down and

bolted to the main one. A 2-phase design has only to be treated

as if it were a 3-phase in regards to rectification. Its overkill,

but I have plenty of new bridges laying about.

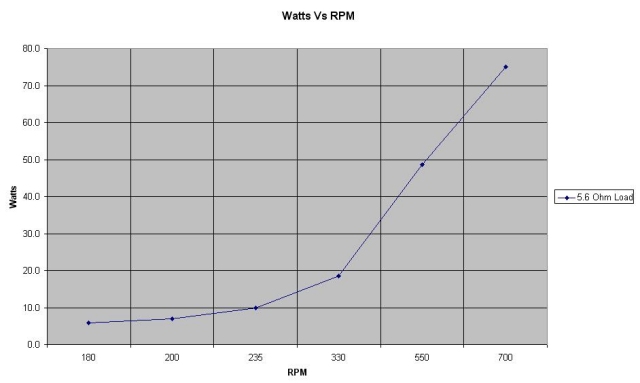

I put the motor back into the lathe and did some tests.

I knew from day one that this would not make much power

due to the 20ohm impedance of each winding. One thing I am

happy with is the waveform. Its an almost perfect sine wave.

The 3hp conversion I did earlier has a slight dip part way

through the wave. I suspect this is caused by a lack of magnets,

as I reduced the magnet count in the final stage of design. I hope

to get some digital waveform images soon.

The rotor can be spun between two fingers to produce 20+

Volts. It feels like a fine stepper motor when it's spun by hand.

I coated the windings with motor winding lacquer for use

in outdoor environments. And the whole outer casing got

a coat of my favourite 97% zinc protective Gal paint.

In conclusion, I'm happy that it performed as I expected it would.

It was a fun test project that produced more information for me

and tested my skills, so that makes it a success. I would call this

a 50-80watt alternator to be conservative. I don't think I could

get much more out of it with the stock windings. Considering that

it began life as a mass produced & average quality domestic motor,

worked for 12 years and then changed roles to produce power is

quite a heart warming thought

I'm going to do a set of wood blades based on Hugh's designs

and adjusted for higher RPM at lower (20-30klm/h) wind speeds.

About 800mm radius blades with a TSR of about 10 should do it.

I also recovered the "gearbox" from the washing machine, and

it seems to be about a 4:1 or thereabouts. It's a planetary style

with a sealed aluminium casing filled with oil, and brass/plastic

gears. I'm having kinky thoughts about using it as a speed up

for the motor - maybe get some serious RPM out of it. Curious,

the oil that was in the gearbox was squeaky clean after 12 years.

Spank me! The gearbox even has a friction brake!!

This is going to be fun

I might set this one up at home in a suburban setting on a fold

over tube tower. It will be excellent for testing blades, MPPT

designs, my PICAXE LCD logger and generally gathering info.

If not, I can see it becoming a battery charger at a friends house

that has strong daily winds. He has a garden light system that runs

for a few hours a night. A full day of wind charging should handle

this no problem.

Costs:

Magnets ~AU$15

Motor - free

Epoxy ~ AU$5

New Bearings ~ AU$12

Rectifiers ~ AU$12

Heatsink - free

Total ~$44

Making power from junk - priceless

sPuDd..